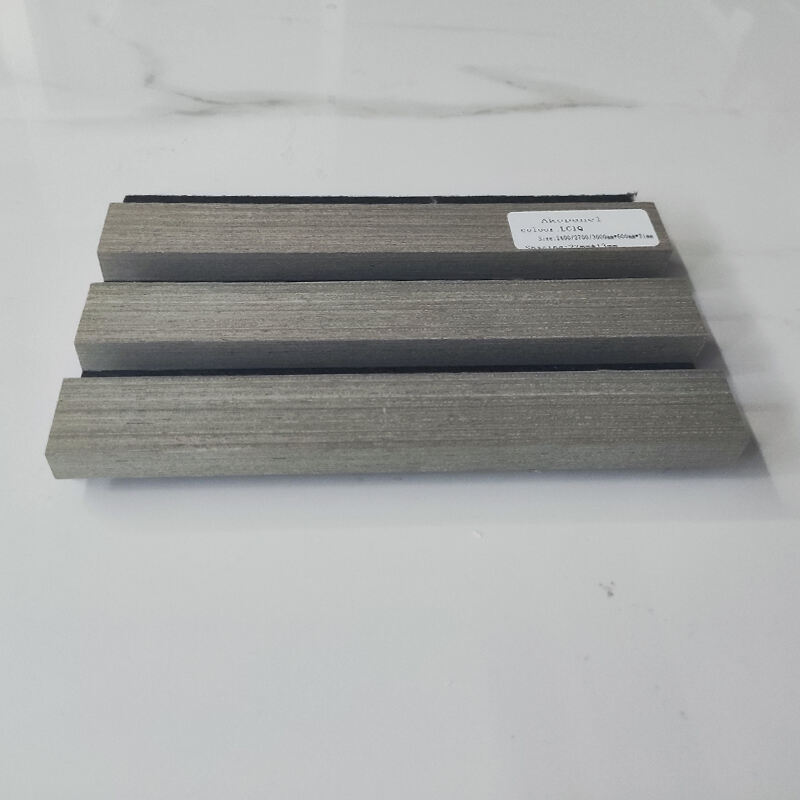

Techos' wood plastic composite (WPC) manufacturing process is a blend of advanced technology and meticulous craftsmanship. It begins with the careful selection of recycled wood fibers and plastics, which are then cleaned, sorted, and prepared for processing. The materials are compounded in precise ratios and heated to create a homogeneous mixture. This mixture is then extruded through specialized dies to form the desired shapes, such as planks for decking, panels for cladding, or profiles for fencing. During extrusion, additives may be incorporated to enhance properties like UV resistance, color stability, and strength. After shaping, the WPC products undergo cooling, cutting, and finishing processes, including sanding, embossing, and coating application, to achieve the final quality and appearance. Rigorous quality control measures are in place at every stage to ensure consistent, high-quality output. Contact us to learn more about our WPC manufacturing expertise and how it benefits your projects.