What is Wood Plastic Composite?

Wood Plastic Composite (WPC) is a good solution for some polyolefins WPC is a such type of material which consists of thermoplastic and wood fibre or wood flour. This material family is generally represented by polyethylene (PE), polypropylene (PP), and polyvinyl chloride (PVC). The wood fibres and the plastic are fully mixed in the extruder, the heating of products are continuously heated and moulded in the process; products are perfect mixing, good dispersion flow easy, mass production of the shape. This process preserves the natural wood appearance, stability and quality, WPC is a timber alternative product which is highly recommended among the new materials. It is worth nothing that WPCs can be manufactured by various process techniques including extrusion and injection moulding which significantly influence the final properties of the product. The differences in methods produce a difference in performance and use of WPCs in different applications, and open new avenues in the construction sector.

Types of WPC: PE, PP, and PVC

According to the kind of plastic, WPC are well categorized into PE, PP, and PVC. To begin, Polyethylene (PE) is highly durable and has excellent moisture resistance making it ideal for outdoor settings where the elements are constantly at play. There is Polypropylene (PP), a versatile material with enough flexibility and rigidity to suit certain design needs. Finally, if you prefer getting the lock that can be used in many areas such as home and business, Polyvinyl Chloride (PVC) is the best as it also has a good cost to wear resistance ratio. It is note worthy to mention that each class of WPC realize particular advantages and, therefore, it is chosen based on the actual requirement of the project, in order to achieve the best solution to various applications.

Key Benefits of Wood Plastic Composite

Durability and Weather Resistance

Wood Plastic Composites (WPC) are well known for their excellent durability resulting from their resistance to harsh weather conditions. Designed to repel water, sun, and changing weather conditions, WPCs keep outdoor structures lasting longer. The not make the product noise dust (all on p.38 of sor:43~50) voisy Areysoryaro undertaken%are also has been succeeded for using in outdoor than wood products becauseʒhave been found that in usual WPC The rot resistance of WPC film better than the wood products. This innate strength not only guarantees the long life of the product, it also reinforces the construction and added value within the project, they are used.

Low Maintenance and Termite Resistance

WPCs do not corrode and are highly resistant to rot, decay, and marine Borer attack, though they do absorb water into the wood fibers embedded within the material. And unlike wood, which must be periodically treated with preservatives to prevent decay and which also creates an attractive home for insects when treated, WPC does not require as much maintenance work, making them popular choices for builders. The components are naturally insect resistant so there is no need to treat with toxic chemicals that might affect your center. This essential quality helps make WPCs the perfect solution for anyone who’s looking for an easy-to-maintain, long-lasting product.

Aesthetic Versatility and Design Flexibility

WPC aesthetic and design flexibility are also unmatched. Such composites can be manufactured in a variety of colors, textures and finishes, to enable them to coexist with a wide range of architectural designs. This flexibility allows the WPCs to be used in a wide range of applications, from modern designs to traditional aesthetics, and the options are endless when it comes to decorating a building facades. These bricks are being adopted more and more in contemporary construction work, affording many possibilities for both a functional and aesthetic use.

In summary, the key benefits of Wood Plastic Composites are clear—they deliver unmatched durability, minimal maintenance needs, and vast aesthetic alternatives, setting a high standard in the realm of innovative building materials.

Applications in Modern Construction and Design

Decking, Fencing, and Outdoor Structures

Wood Plastic Composite (WPC) to be new material of choice for professional deck builders and contractors as well as homeowners looking for a great deck for a great value. This has made WPC a popular choice for homeowners and builders who are looking for an end product that offers a plush body with an even and soothing texture. Moreover, WPC based fences are in high demand because of their long-lived thermal and weather resistance, that help it look new even after many years of use. It is further complemented by a low maintenance appeal which is perfect for your outdoor structure that looks stunning while aging naturally over time.

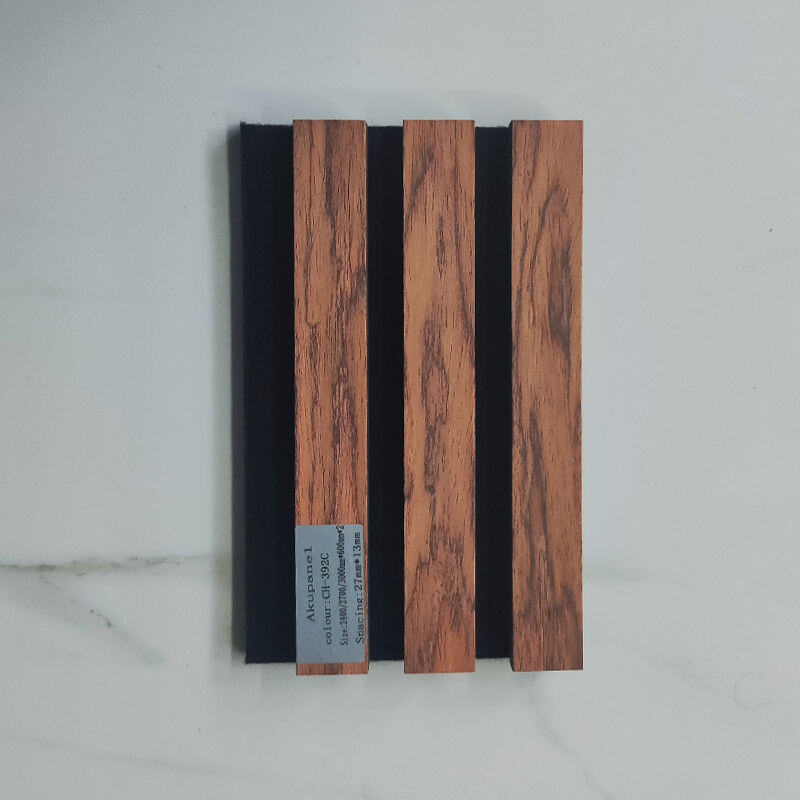

Acoustic and Soundproof Wall Panels

WPC is also gaining popularity in the acoustic solutions market, and the soundproof wall panels is also on the up. These panels are used to improve ambient noise in residential and commercial spaces, making a significant contribution to the evolution of modern urban life; reducing noise pollution and distracting sounds is one of our main companies’ objectives. It is found from studies that the acoustical insulation performance of WPC is much better and it can reduce 30dB noise transmission because of the density and material of the product (such as including PVC), which is the effective way to avoid the noise pollution and create the perfect indoor environment. With the increasing popularity of acoustic wall panels, WPC is playing an integral role in bringing modern soundproofing needs to fruition.

Decorative Panels for Interior and Exterior Use

WPC decorative panels are more and more widely-used in interior decoration and side have taken place of traditional interior panels. These panels can look just like real wood, but without wood's susceptibility to pests and the elements. These panels can be easily incorporated into any interior or exterior design for content texture and form. The flexibility of these common pool are easy to accommodate depending upon today's design specifications, thus maker WPC the best choice for discerning architects and designers, striving to satisfy the needs of contemporary working styles.

Environmental Impact and Sustainability

Recycled Materials and Circular Economy

Wood Plastic Composite (WPC) products are made of recycled wood fibers and thermoplastic(s), which are being affected deep into the wood fibers during the production process. In doing so, it decreases how much ending up in landfills, which also benefits the environment. In addition, it reduces the consumption of resources through the recycling of the material. This methodology not only contributes to sustainability, but also fosters green innovation in the construction sector. In WPC, the recycled content allowance will clearly exhibit an environmental advantage of using this material over conventional building materials. It's a sign of a move away from the throwaway: toward 'responsible' production that values things lasting and saving precious resources.

Reducing Carbon Footprint in Construction

The utilization of WPC in construction provides an opportunity to achieve carbon goals, both from a resource exchange and an emission-reduction standpoint. The milling process used in producing wood powder requires less energy in comparison with other processes for obtaining wood flour. This energy saving also applies to less emissions to the atmosphere, since those are not produced during processing of WPC. As reported in industry studies, the use of WPC can greatly reduce a project’s total carbon footprint, further reinforcing sustainability goals. Thus, WPCs represent a promising environmentally friendly product that meets demands for reduced environmental impacts in the construction industry with adequate quality and performance levels. The shift is indicative of a broader industry trend towards sustainability and draws attention to the advantages of lower carbon footprints of WPC.

Market Trends and Future Outlook

Asia-Pacific Dominance and Regional Growth

The Asia Pacific region is forecasted to be the largest market of Wood Plastic Composite (WPC), followed by Europe and North America, with strong growth prospects. Owing to its notable market share estimated at about 57% in 2023, the region is anticipated to continue its lead through 2029, registering a CAGR of 7% over the same period, as stated in “Wood Plastic Composites Market – A Global Market Overview”. A number of factors are driving this trend, not least among which is regional momentum in the form of government programs to promote sustainable building. It was especially important projects, as they lead to increased use of environmentally friendly materials, such as WPC, reducing the use of traditional building materials and contribute to environmental objectives. Moreover, it is countries such as China, India, and South Korea leading the way, that are utilising the benefits of WPC in response to an increasing population and the demand for infrastructure; utilising the advantages that WPC has to offer.

Innovations in Eco-Friendly WPC Technology

New technologies are being developed that are transforming the capabilities of WPC products by using both re-tooled and new equipment. Thomas Busskamp continued: "Product developments concentrate on the combination of bioplastics, as well as the effectiveness of the recycling process required for them: A high-quality end product should be produced, that meets the consideration of being environmentally friendly." These state of the art technologies make WPC a leader in green building materials and help to offset several limitations of traditional construction materials. Environmental issues, which have led to the development of bio-based WPC, have advantages such as renewable materials not relying on petroleum-based materials. According to 2018 industry research, these advances in technology not only increase the appeal of the material, but empower its uses across a wide range of markets, including automotive and consumer goods, making WPC a building material of the future for projects large and small.