Why PVC Wall Paneling Is Gaining Popularity in Modern Interiors

Rising Demand in Residential and Commercial Spaces

Over 62% of renovation projects in 2024 now specify synthetic wall solutions, with PVC paneling leading adoption in home kitchens and retail interiors. Builders increasingly favor materials that perform across multifunctional environments—from moisture-heavy restaurants to high-traffic office lobbies—driving the shift toward durable, adaptable wall systems.

Key Advantages: Moisture Resistance and Low Maintenance

PVC panels hold up pretty well even when humidity hits around 90%, according to the ASTM D3273 test standards. That makes these panels great choices for places where moisture is always an issue like bathrooms and laundry areas. The surface doesn't absorb water so mold has trouble growing on it too. Cleaning takes just about 15 minutes each month which cuts down on maintenance work by roughly 60% compared to regular tile walls. And here's another plus point over traditional options: while paint peels and wallpaper starts to bubble after being exposed to constant dampness, PVC stays intact without showing signs of wear. No need to constantly patch holes or replace sections every few years as would happen with other materials in similar environments.

Market Shift from Wallpaper and Paint to Synthetic Panels

According to the latest Interior Design Materials Report from 2023, around 41 percent of designers are going with PVC instead of those old school finishes because it makes budgeting much easier. Let's look at the numbers for a second. Wallpaper typically runs between two to five dollars per square foot upfront, but PVC actually cuts down on what we call long term costs by about half over ten years since there's no need for constant repainting or replacing adhesives. And here's another perk that might surprise some folks. With heat transfer printing technology, manufacturers can now create really convincing ceramic tile and natural stone looks too, all while keeping material costs roughly thirty percent below traditional options.

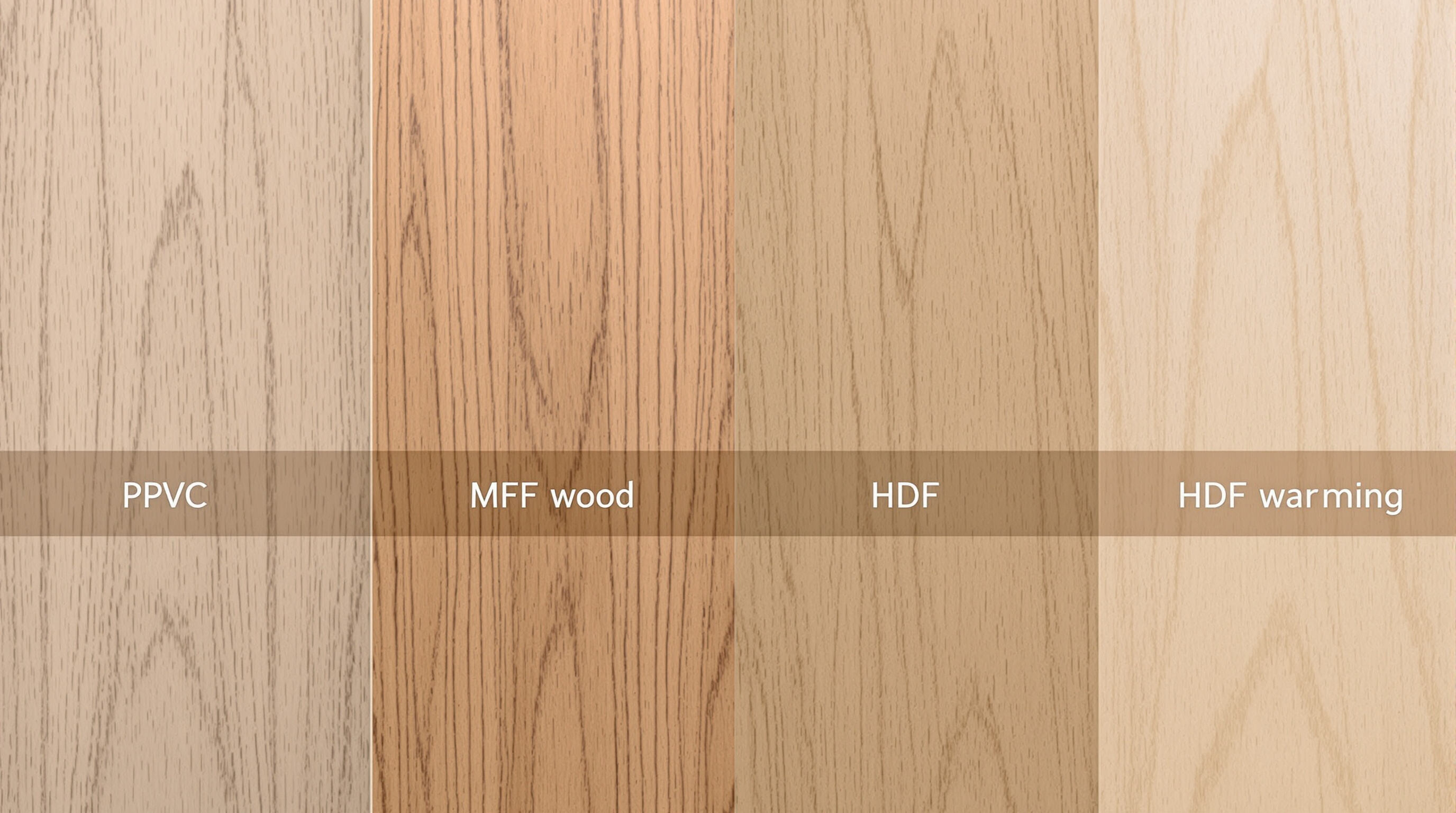

Material Comparison: PVC vs. Wood, MDF, and HDF Wall Panels

Structural Differences Between PVC and Wood-Based Panels

PVC panels come from this stuff called polyvinyl chloride polymer, which gets pressed into those smooth, consistent sheets we see everywhere. On the flip side, materials like MDF and HDF work quite differently. They basically mix up wood fibers with some kind of resin glue and then smash them together under intense pressure. Because of how they're constructed, PVC naturally resists water pretty well. Wood based products tell a different story though. Tests show these panels tend to soak up around 7 to 12 percent of surrounding humidity. That means when conditions get damp, they start swelling and eventually break down over time, making them less reliable for certain applications.

Performance in Moisture-Prone Areas Like Bathrooms and Kitchens

PVC maintains dimensional stability even at 95% humidity, whereas MDF swells by 15% after 72 hours of water exposure (Material Durability Report 2023). In kitchen splash zones, HDF shows warping within 6–8 months in 82% of installations, compared to PVC’s 96% warp-free performance over five years under similar conditions.

Durability in High-Traffic Environments: PVC vs. MDF/HDF

| Factor | PVC Panels | MDF/HDF Panels |

|---|---|---|

| Scratch Resistance | 8/10 | 4/10 |

| Impact Resistance | 9/10 | 5/10 |

| Maintenance Frequency | Every 5 years | Every 18 months |

Field tests show PVC withstands 3.7x more impacts than HDF in commercial corridors before showing visible damage (2024 Architectural Materials Study).

Long-Term Value Under Environmental Stress and Wear

Wood based panels just don't hold up as well in those mixed climate areas where it gets both hot and humid. They need replacing roughly twice and a half times more frequently than PVC alternatives do. Take a look at the numbers from the Building Materials Sustainability Index 2023 report: MDF tends to last around four years give or take, whereas PVC systems can stick around for nearly twelve years before needing attention. The reason? PVC has this smooth surface that keeps out most molds. Studies show it stops about 98 percent of typical mold growth, which means fewer headaches down the road. And when mold does become an issue, fixing it costs between eighteen and twenty two dollars extra per square foot if using HDF instead of PVC. That adds up pretty quickly over time.

PVC vs. Laminate and WPC: Durability, Cost, and Climate Performance

WPC vs. PVC Durability in Humid and Tropical Climates

When it comes to handling damp conditions, Wood Plastic Composites (WPC) and PVC behave quite differently. PVC basically doesn't absorb much water at all, sitting around 0.5% or less, while WPC soaks up between 0.8 to 1.5% when humidity hits about 85%. That might not seem like much on paper, but it makes a big difference in practice. While WPC does handle warping better than regular wood, there's a catch. The cellulose in these composites tends to attract mold if left unprotected, which means they need sealing treatments especially important for areas where rain happens often. For anyone building decks or outdoor furniture in places like Florida or Southeast Asia, PVC just has that advantage over WPC materials because it stands up better against constant moisture exposure.

Cost Analysis: Upfront Price Versus Lifecycle Value

The initial price tag on PVC is typically around 15 to 20 percent cheaper compared to those high end WPC systems. But wait there's something else going on here. While WPC materials tend to last about 25 years before needing replacement, this makes them actually cheaper in the long run when looking at things like hospitals or hotels where regular maintenance matters a lot. When we talk about homes though, PVC still wins out because people want to save money right away. The yearly upkeep costs work out to about 18 cents per square foot for PVC versus 12 cents for WPC. Most homeowners just aren't willing to pay extra now for savings that won't show up until much later.

Moisture Resistance and Structural Integrity Over Time

Accelerated aging tests simulating decade-long exposure show PVC retains 98% of its flexural strength in wet environments, while WPC degrades 30% faster due to cellulose breakdown under constant moisture. Both materials outperform laminate, which delaminates at three times the rate of PVC in steam-heavy kitchens.

Maintenance Needs and Material Lifespan Comparison

| Factor | PVC | WPC |

|---|---|---|

| Cleaning Frequency | Biannual | Annual |

| Surface Refinishing | Not required | Every 7–10 years |

| UV Resistance | Moderate | High |

| Repair Complexity | Panel replacement | Partial resurfacing |

While WPC offers superior colorfastness in sunlight, PVC’s stain-resistant surface simplifies cleaning and replacement, especially in high-use areas.

Installation and Application Flexibility of PVC Wall Paneling

Ease of Installation Compared to Traditional Wall Coverings

PVC wall panels make home renovations much easier thanks to their light weight and snap-together design. No need for messy grout, special glues, or all that time-consuming surface preparation. Traditional tile work demands perfect alignment and long waiting periods for adhesive to cure while wallpaper installation requires spotless walls. With PVC, homeowners can install these panels right over bumps and cracks commonly found in bathroom and kitchen walls. According to recent industry reports, installation times have dropped around 60 something percent when using modern PVC systems. Many people actually finish installing them themselves within five hours or so on average. Plus, if one panel gets damaged down the road, it's simple enough to replace just that single section without tearing out surrounding areas. This kind of flexibility really stands out against options like painted drywall which needs repainting after any damage or laminate surfaces where mistakes mean replacing large sections.

Suitability for Residential Versus Commercial Environments

PVC really shines in home environments where moisture is a constant problem, think bathroom walls around showers or basement floors. Unlike wood products that tend to warp and grow mold over time, PVC stands up to these conditions without complaint. For businesses, the material's toughness makes it ideal for places where people walk all day long, like hospital hallways or busy kitchen areas in restaurants. The stuff just doesn't wear down like other materials would, plus it wipes clean quickly after spills or messes. Homeowners love how modern PVC can mimic natural materials too, with realistic wood grain patterns or marble looks that don't require sealing. Meanwhile, heavier duty versions pass strict safety tests needed in schools and medical buildings, handling chemicals and resisting flames when required. What makes PVC so popular across both markets? It basically takes care of itself, which means fewer repairs and less money spent on replacements down the road.

Sustainability, Aesthetics, and Long-Term Value of PVC Wall Panels

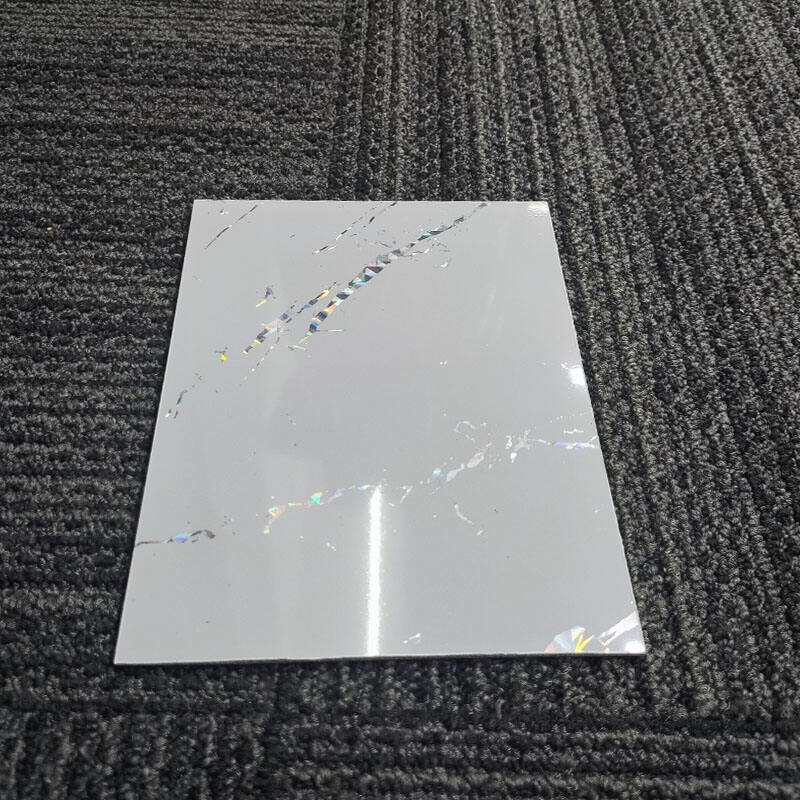

Aesthetic Versatility: Design, Texture, and Finish Options

PVC comes with more than 50 different finish options these days, from convincing wood grain looks to stone-like textures, giving designers way more freedom than old school materials ever did. The latest production techniques let manufacturers create those cool 3D embossed patterns and even metallic finishes that look pretty much the same in every room they're installed. And here's something else most people don't realize: regular paint tends to chip away after a while, and wallpaper just fades out completely. But PVC stands up to all sorts of conditions, whether it's high humidity levels or direct sunlight exposure, so it keeps looking good year after year without needing constant touch ups or replacements.

Durability and Maintenance vs. Wallpaper and Painted Walls

PVC panels last 3–4 times longer than wallpaper (15–25 years vs. 3–7 years) and require 80% less maintenance (2023 building materials study). Their non-porous surface resists stains, scratches, and microbial growth, eliminating repainting and re-papering cycles. In kitchens, PVC outperforms paint by 92% in humidity resistance, according to waterproofing tests.

Environmental Impact: Recyclability and Production Footprint

Even though PVC comes from fossil fuels, many argue that its long life span of around 30 years plus the fact that it can actually be recycled up to seven times makes a real difference. Studies suggest this recycling process cuts down about 40 percent of what would otherwise be carbon emissions if we were using ceramic tiles instead. Most manufacturers these days, something like over two thirds according to recent industry surveys, have started incorporating recycled materials into their production lines which means they don't need as much new plastic. And there's another benefit too. The material's insulating qualities help buildings save on energy costs throughout the year. We're talking roughly between 12 and maybe even 18 percent less heating and cooling expenses in those moderate climate zones where temperatures aren't extreme. That figure comes straight out of last year's energy efficiency report published in 2024.

Balancing Durability and Eco-Friendliness in Modern Interiors

Architects increasingly specify PVC for projects pursuing sustainability certifications (LEED, BREEAM) alongside heavy-use durability. Unlike biodegradable alternatives that degrade quickly, PVC combines decades-long performance with 100% recyclability—meeting commercial ROI goals and residential eco-conscious expectations alike.

FAQ

What are the main benefits of PVC wall paneling?

PVC wall paneling offers numerous benefits such as moisture resistance, low maintenance, durability in high-traffic environments, and aesthetic versatility with various design and finish options.

How does PVC compare to wood-based panels?

PVC panels are more moisture resistant than wood-based panels like MDF and HDF, making them a better choice for humid environments. PVC also offers better durability and maintenance advantages.

Is PVC more cost-effective than traditional materials?

Yes, PVC tends to be more cost-effective in the long run due to reduced maintenance and replacement costs compared to materials like wallpaper and paint.

Can PVC panels be used in both residential and commercial settings?

Absolutely, PVC panels are suitable for both residential and commercial environments, offering flexibility in installation and application across various spaces.

What is the environmental impact of using PVC panels?

PVC panels have a lower environmental impact due to their recyclability and long lifespan. They help reduce energy costs in buildings and are recyclable up to seven times.

Table of Contents

- Why PVC Wall Paneling Is Gaining Popularity in Modern Interiors

- Material Comparison: PVC vs. Wood, MDF, and HDF Wall Panels

- PVC vs. Laminate and WPC: Durability, Cost, and Climate Performance

- Installation and Application Flexibility of PVC Wall Paneling

- Sustainability, Aesthetics, and Long-Term Value of PVC Wall Panels

- FAQ