Understanding Wall Panel Materials and Their Maintenance Needs

Common types of wall panel materials: wood, laminate, vinyl, and PVC

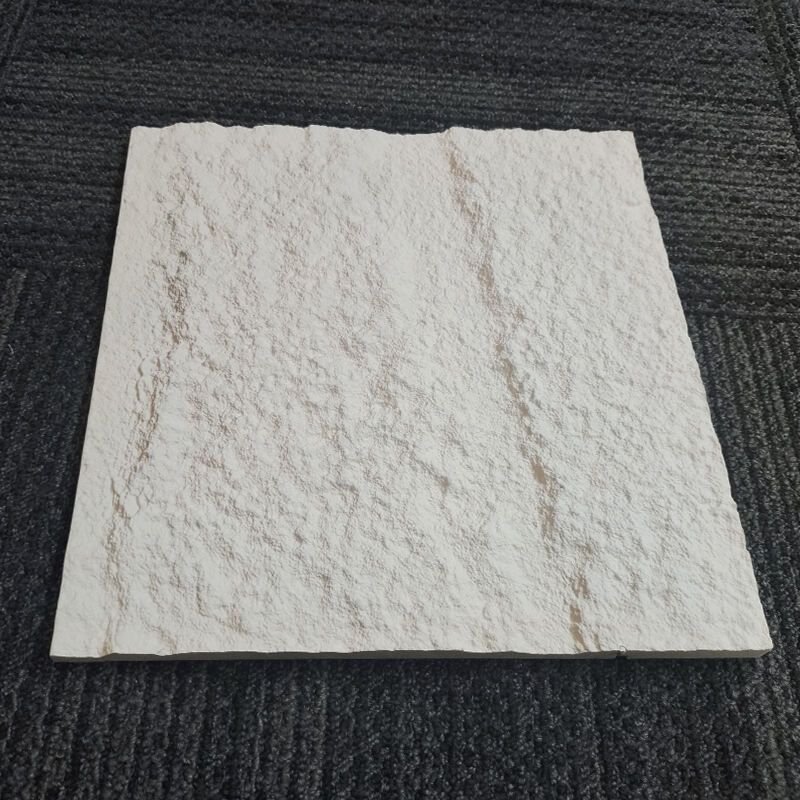

Wood panels offer timeless elegance but require regular conditioning to prevent drying. Laminate panels mimic natural materials using layered composites, while vinyl and PVC provide water-resistant solutions ideal for high-moisture areas. Each material’s density, porosity, and chemical sensitivity dictates unique care protocols.

How material composition affects cleaning methods for different wall panel materials

Porous wood absorbs spills, requiring pH-neutral cleaners to avoid finish degradation. Non-porous vinyl resists moisture but can warp when exposed to alcohol-based sanitizers. A 2024 materials study found abrasive tools scratch laminate’s melamine layer three times faster than soft microfibers, highlighting the importance of appropriate cleaning techniques.

Recommended cleaning products by panel type to avoid damage

- Wood: Oil-based polishes (e.g., beeswax blends)

- Laminate: Ammonia-free glass cleaners

-

Vinyl/PVC: Diluted vinegar solutions (1:4 ratio with water)

Manufacturer testing by WPC specialists confirms these combinations reduce surface erosion by 41% compared to generic detergents.

The role of finish coatings in protecting wall panels from wear

Polyurethane-sealed wood withstands 68% more wear cycles than unsealed variants (NAHB, 2022). UV-resistant acrylic layers on PVC prevent color fading in sun-exposed rooms. Reapplying protective coatings every 3–5 years maintains hydrophobicity and scratch resistance.

Daily and Seasonal Cleaning Routines to Preserve Wall Panel Integrity

Effective Daily Maintenance to Prevent Dirt Buildup and Staining

Keeping up with regular maintenance really helps stop surfaces from wearing down over time. A good habit is dusting panels regularly using a soft microfiber cloth, which picks up those tiny abrasive bits before they get a chance to scratch the finish. For spots that see a lot of foot traffic, give them a proper wipe down once a week with a slightly damp cloth and something like a pH neutral cleaner works best. Pay special attention to those grooves and corners where dirt tends to hide out. The difference between daily cleaning versus weekly maintenance adds up too panels that get tended to every day need about half as many thorough cleanings throughout the year, saving both time and effort in the long run.

Safe Cleaning Techniques Using Mild Detergent and Non-Abrasive Tools

Most panel surfaces can be cleaned effectively by mixing a single teaspoon of regular dish soap into about a quart of warm water. When applying this solution, grab a soft sponge or microfiber mitt and move in gentle circles across the surface. This helps lift away dirt and grime without messing up those factory applied protective layers. Now when dealing with rougher textures such as those imitation wood grain panels, switch out the sponge for something with softer bristles. These specialized brushes get into all those little nooks and crannies without scratching off any of the intricate detailing that makes these surfaces look so realistic. Just be careful not to scrub too hard on these kinds of materials.

Avoiding Harsh Chemicals That Compromise Wall Panel Surfaces

Tests have shown that bleach, ammonia cleaners, and acidic products can wear down panel finishes at triple the normal rate. What these cleaning agents do is actually remove those protective UV resistant coatings from vinyl surfaces while making laminated panels look faded and worn over time. When choosing cleaning products, it's best to go with ones specifically labeled as safe for the panel material in question. Neutral pH cleaners tend to work well on most common materials including PVC, wood composites, and acrylics without causing damage. Just be careful not to let harsh chemicals sit too long on any surface before wiping them away.

Seasonal Inspection for Cracks, Loose Sections, and Early Signs of Wear

Check things out once a quarter with what some folks call the tap test. Just run your knuckles lightly over those panels and listen for any hollow spots where the sound changes pitch. That usually means the glue has failed somewhere underneath. For gaps between panels, grab a regular old credit card and slide it in there. If it fits more than about 1.5 millimeters deep, that's probably because of moisture causing expansion issues. Most experts suggest going back and sealing those edges again somewhere around 18 to 24 months later if we're talking about areas with high humidity levels. Keep notes on what you find during these checks so we can see where problems tend to pop up most often and fix them before they get worse.

Environmental Control to Prevent Moisture and UV Damage

Managing Humidity and Temperature to Prevent Warping in Wood and Composite Panels

Wood and composite wall panels perform best at stable humidity levels (45–55%). Daily temperature swings exceeding 15°F can cause irreversible expansion in wood fibers or delamination in composites. Install hygrometers near panels, especially in moisture-prone areas like bathrooms and basements, to monitor environmental conditions.

Using Dehumidifiers and Ventilation in High-Moisture Areas

In kitchens, laundry rooms, and similar spaces, operate dehumidifiers for 4–6 hours daily during humid seasons. Combine with cross-ventilation—open opposing windows for 30-minute intervals—to promote air circulation without allowing moisture buildup. Set HVAC fan modes to "Auto" to minimize redistribution of damp air.

Protecting Wall Panels from UV Fading with Window Treatments and Strategic Placement

About 70% of the color loss we see in vinyl and laminate panels over time comes down to UV damage within just five years according to industry data. To protect against this, many homeowners install those special window films that filter out almost all UVA and UVB radiation, sometimes blocking as much as 99%. Another good option works especially well in bright rooms where sunlight hits hard - layering regular curtains with blackout liners can do wonders too. And don't forget about rotating furniture throughout the seasons. Moving big pieces around lets panels in shadowed areas get some light while preventing others from fading faster than their neighbors. This simple practice helps maintain an even appearance across the entire space.

Preventing and Repairing Physical Damage to Wall Panels

Minimizing Scuffs, Dents, and Furniture-Related Damage Through Protective Measures

Putting felt pads under furniture legs, installing door bumpers, and adding guardrails in areas where people walk a lot can really help stop damage over time. Leaving about 2 to 3 inches of space between furniture and walls works wonders too. According to research published last year in an interior design journal, keeping that little bit of clearance cuts down on wall scuffs by nearly four fifths. For families dealing with energetic kids or playful pets, those transparent acrylic panels that slide into place along the bottom part of walls make excellent protection against accidental marks while still letting the room look clean and uncluttered.

Repairing Scratches and Dents in Wood and Composite Panels With Touch-Up Kits

Minor damage in wood or composite panels can be repaired with color-matched fillers and texture-replicating tools. Use polymer-based compounds for composites and wax sticks or stain pens for real wood. Apply filler sparingly, sand lightly, and seal with a matte protectant to blend repairs seamlessly into the surrounding surface.

When to Choose DIY Repairs Versus Professional Restoration Services

DIY fixes are suitable for superficial damage less than ¼-inch deep. For large dents, structural cracks, or delaminated layers, professional restoration is recommended—improper repairs can worsen the issue. Professional service becomes cost-effective when damage exceeds 15% of a panel’s surface area or affects load-bearing sections.

Long-Term Care: Refinishing and Proactive Maintenance Planning

Refinishing Aged or Faded Wall Panels to Restore Appearance and Protection

UV exposure and moisture degrade finishes over time. Light sanding followed by oil-based stains rejuvenates wood panels, while composites respond well to acrylic sealants. For vinyl and PVC, use specialized UV-resistant polishes that maintain flexibility and prevent chalkiness.

Applying Sealants, Oils, and Topcoats to Extend the Lifespan of Wall Panels

Apply water-repellent sealants twice yearly to protect wood from swelling. Silicone-based coatings help fill micro-cracks in composite panels. Avoid petroleum-based products on PVC, as they compromise structural integrity. Proper sealing reduces replacement needs by 34% (NAHB, 2022).

Developing a Long-Term Care Plan to Maximize Wall Panel Durability

Create a 5-year maintenance schedule aligned with material warranties:

- Annual deep cleaning with pH-neutral solutions

- Triannual sealant reapplication in high-traffic zones

- Post-season inspections after extreme weather

Data Insight: 68% of Panel Failures Stem From Lack of Seasonal Inspection (NAHB, 2022)

Include thermal imaging during seasonal transitions to identify hidden moisture in wall cavities. Facilities following structured maintenance plans report 41% fewer panel replacements over ten years compared to reactive approaches.

FAQ

What are the most common types of wall panel materials?

The most common types of wall panel materials include wood, laminate, vinyl, and PVC.

How should I clean wood wall panels?

Wood panel care includes using oil-based polishes like beeswax blends, avoiding harsh cleaners, and regular dusting with a soft microfiber cloth.

Can I use harsh chemicals on wall panels?

Harsh chemicals such as bleach, ammonia cleaners, and acidic products should be avoided as they can wear down panel finishes rapidly.

How often should protective coatings be reapplied to wall panels?

Protective coatings should typically be reapplied every 3 to 5 years to maintain hydrophobicity and scratch resistance.

When is it recommended to seek professional restoration for wall panels?

Professional restoration is recommended for significant damage, like large dents or structural cracks, or when damage affects more than 15% of a panel’s surface area.

Table of Contents

- Understanding Wall Panel Materials and Their Maintenance Needs

- Daily and Seasonal Cleaning Routines to Preserve Wall Panel Integrity

- Environmental Control to Prevent Moisture and UV Damage

- Preventing and Repairing Physical Damage to Wall Panels

-

Long-Term Care: Refinishing and Proactive Maintenance Planning

- Refinishing Aged or Faded Wall Panels to Restore Appearance and Protection

- Applying Sealants, Oils, and Topcoats to Extend the Lifespan of Wall Panels

- Developing a Long-Term Care Plan to Maximize Wall Panel Durability

- Data Insight: 68% of Panel Failures Stem From Lack of Seasonal Inspection (NAHB, 2022)

- FAQ