What Are UV Marble Sheets? Composition and UV Coating Technology

Definition and Core Structure of UV Marble Sheets

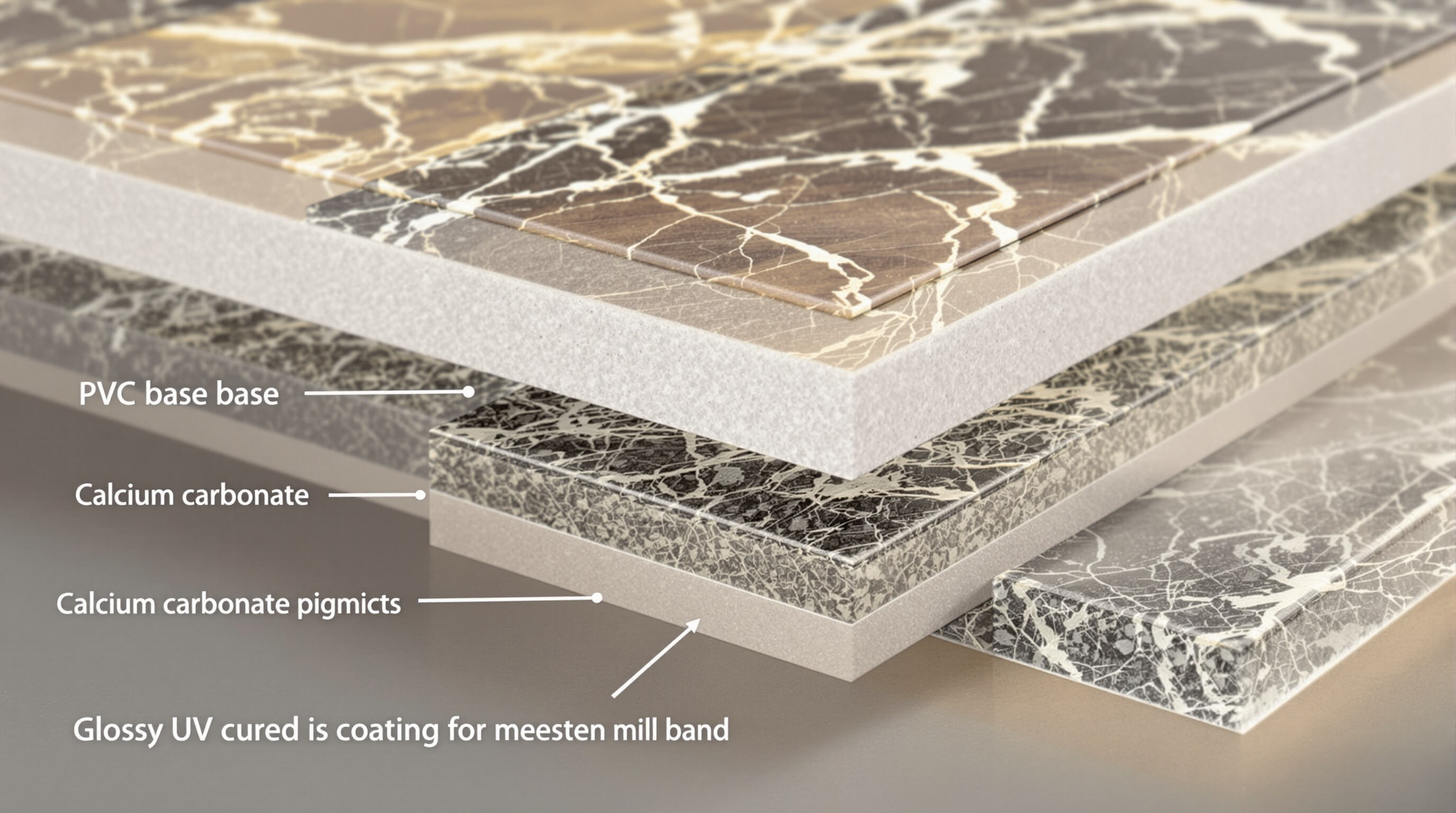

UV marble sheets are engineered decorative panels that combine polymer technology with high-resolution printing to replicate the appearance of natural marble. Their layered structure consists of:

- PVC base layer (40%): Offers flexibility and moisture resistance

- Calcium carbonate fillers (45%): Provides rigidity and a stone-like texture

- UV-cured topcoat (10%): Delivers scratch resistance and a high-gloss finish

- Pigments and additives (5%): Ensure color vibrancy and UV stability

This construction eliminates the brittleness of natural marble while achieving 98% visual accuracy to quarried stone, as verified by material testing labs (2023).

The Role of UV Curing in Enhancing Surface Durability

UV curing uses ultraviolet light at 385–405 nm wavelengths to instantly harden liquid coatings into a durable, cross-linked polymer matrix. This process:

- Reduces curing time from over 24 hours (for traditional varnishes) to just 2–3 minutes

- Produces a surface 3× denser than air-dried finishes

- Achieves 4H pencil hardness, significantly improving scratch resistance

UV-cured surfaces endure 15,000+ scrub cycles without gloss degradation, making them ideal for high-traffic commercial walls and retail displays.

Visual Realism: How UV Printing Replicates Natural Marble Aesthetics

High-definition UV printing for authentic marble textures

The UV marble sheets rely on advanced UV printing technology with around 2400 DPI resolution to replicate the complex details seen in real marble. This includes those beautiful vein patterns, tiny mineral spots, and how light bounces off surfaces similar to what we see in top quality marbles such as Carrara White or Portoro Gold. Recent tests done last year showed something interesting too the printed layers keep about 95 percent of their original clarity even after being installed. That means no more dealing with that fake glossy look that cheaper options tend to develop over time.

Design consistency and elimination of natural flaws like color variation

Unlike natural marble, which suffers from color variation, fissures, and staining risks, UV marble sheets use digital spectral matching to maintain ±2% hue deviation across batches. This ensures uniform appearance in large installations, making them ideal for hotel lobbies and corporate interiors requiring visual continuity.

Range of aesthetic options and customization potential

UV tech goes way beyond just copying the look of over 200 different natural stones. It actually makes possible some pretty cool designs that don't exist in nature at all, like those copper vein effects in Nero Marquina or the beautiful gradients seen in Calacatta Blues. For architects wanting something special, they can ask for completely custom patterns tailored exactly to their project size. Most manufacturers these days will send digital samples too, about two thirds of them actually getting those proofs out within three days. We're seeing more businesses pick specific color schemes too, especially when trying to keep their brand consistent throughout various areas of a building. From front desk counters all the way down to elevator interiors, companies want that high end marble appearance without breaking the bank on real stone.

Cost-Effectiveness and Long-Term Value Compared to Natural Marble

Upfront Cost Comparison: UV Marble Sheets vs Natural Marble

UV marble sheets offer luxury aesthetics at 60–70% lower initial cost than natural marble. While natural stone costs ₹1,500–₹5,000 per sq. ft (including quarrying and polishing), UV sheets range from ₹200–₹500 per sq. ft. Their lightweight nature reduces installation time and labor needs, cutting associated costs by up to 75%.

| Factor | UV Marble Sheets | Natural Marble |

|---|---|---|

| Material Cost (per sq. ft) | ₹200–₹500 | ₹1,500–₹5,000 |

| Installation Time | 6–8 hours | 24–36 hours |

| Labor Cost | ₹800–₹1,200/day | ₹2,500–₹4,000/day |

Affordable Luxury with Minimal Maintenance Expenses

UV-coated surfaces are non-porous and stain-resistant, requiring only a damp cloth for cleaning. Unlike natural marble, they do not need annual sealing (₹5,000–₹10,000/year) or waxing, reducing maintenance costs to under ₹1,000 annually.

Price Range of UV Marble Sheets in the Indian Market

In India, UV marble sheets (4x8 ft) are priced between ₹1,500 and ₹3,500 per sheet, depending on thickness (2–6 mm) and design complexity. Bulk commercial orders typically receive 15–20% discounts.

Lifespan and Return on Investment Over Time

UV marble sheets last 25–30 years in residential and commercial environments. Their resistance to scratches, fading, and humidity ensures a return on investment within 5–7 years—particularly valuable for hotels, clinics, and rental properties seeking rapid payback.

Durability and Performance in High-Moisture and High-Traffic Areas

Scratch, Water, and Moisture Resistance of UV Marble Sheets

UV marble sheets have a special construction with a polymer composite core underneath a UV coating enhanced with ceramic nanoparticles. These materials reach around 3H pencil hardness according to standard tests like ASTM D3363. What really sets them apart is their completely non porous surface that stops water from soaking in at all. Natural marble just cant compete here since it tends to absorb between 0.08 and 0.14 percent moisture each year when exposed to regular humidity levels. Lab tests indicate these synthetic sheets keep their original color even after being subjected to over 1500 hours of direct sunlight and can handle environments with nearly 98% humidity without fading or degrading. The secret seems to lie in how little moisture actually gets absorbed by the protective coating.

Performance in Kitchens, Bathrooms, and Commercial Spaces

Retail stores have found that UV treated marble surfaces can handle around five to seven daily cleanings before showing any signs of wear, which is way better than regular PVC options that start getting cloudy after just six to twelve months of use. These materials also hold up remarkably well in bathroom settings where steam is constant companionship; we've seen installations last over three full years without any warping issues or layers coming apart. For commercial kitchen operators, the savings really add up too. Maintenance expenses drop by roughly sixty percent when switching from traditional stone surfaces because there's absolutely no need for periodic sealing or those aggressive chemicals that most natural stones require for upkeep.

Low Maintenance and Long-Term Structural Integrity

For regular cleaning, just grab any pH neutral detergent off the shelf. There's absolutely no need for special polishing treatments or resealing procedures. What makes these materials so durable? They have this special polymer structure that basically ignores temperature changes. Even when temps drop below freezing or climb above room temperature, the material stays stable between minus ten degrees Celsius all the way up to fifty five degrees. When installed correctly, these UV treated marble sheets can stick around for anywhere between fifteen to twenty years inside residential spaces. Commercial buildings see them lasting around eight to twelve years before needing replacement. That actually beats out traditional natural marble which usually lasts about ten to fifteen years under comparable circumstances.

UV Marble Sheets vs PVC Marble Sheets: Key Differences and Advantages

Material Composition and Finish Quality: UV vs PVC

UV marble sheets consist of a PVC core with a UV-cured acrylic topcoat, creating a hard, glass-like surface resistant to scratches and fading. In contrast, PVC marble sheets use a single-layer PVC structure with a printed film overlay, resulting in a flatter, less realistic finish.

| Feature | UV Marble Sheets | PVC Marble Sheets |

|---|---|---|

| Surface Hardness | 3H–4H (scratch-resistant) | 2H–3H (moderate scratch resistance) |

| UV Resistance | Maintains color for 10+ years | May yellow or fade after 3–5 years |

| Aesthetic Depth | 3D texture mimicking natural stone | Flat, less realistic finish |

Why UV Sheets Offer Superior Aesthetics and Durability

When UV curing happens, it actually creates a chemical bond between the coating material and whatever surface it's applied to. What this does is form something really special - a surface that looks completely smooth and doesn't have those tiny holes we usually find in other coatings. These surfaces just don't let water get through and they stand up pretty well against scratches too. Some independent testing labs have run experiments showing that these UV treated sheets keep about 95 percent of their original shine even after being cleaned 5,000 times! That's way better than what most PVC sheets can manage, which typically lose around 30 to 40 percent of their gloss under similar conditions. Because of how tough they are, these materials work much better in places like kitchens and bathrooms where there's always lots of moisture around. We've seen firsthand how regular PVC stuff tends to break down over time in these environments.

Addressing Misleading Marketing of PVC as “Marble”

Some manufacturers label PVC sheets as “marble-effect” despite their low heat tolerance—softening at 60°C, compared to UV sheets that withstand up to 120°C. Always verify technical specifications: authentic UV marble sheets specify UV curing times (15–30 seconds) and coating thickness (8–12 microns) in product documentation, ensuring informed purchasing decisions.

FAQ

What are UV marble sheets made of?

UV marble sheets consist of a PVC base layer, calcium carbonate fillers, a UV-cured topcoat, and pigments and additives for color vibrancy and stability.

How do UV marble sheets compare to natural marble in terms of cost?

UV marble sheets are 60-70% less expensive than natural marble and require fewer labor and installation costs, providing significant savings.

Are UV marble sheets durable in high-moisture areas?

Yes, UV marble sheets have high resistance to water and moisture, making them suitable for bathrooms and kitchens.

How long do UV marble sheets last?

UV marble sheets last 25-30 years in residential and commercial environments, providing a long-term return on investment.

What is the difference between UV and PVC marble sheets?

UV marble sheets have a UV-cured acrylic topcoat providing better scratch resistance and aesthetics, while PVC sheets have a single-layer structure resulting in less realistic finishes.

Table of Contents

- What Are UV Marble Sheets? Composition and UV Coating Technology

- Visual Realism: How UV Printing Replicates Natural Marble Aesthetics

- Cost-Effectiveness and Long-Term Value Compared to Natural Marble

- Durability and Performance in High-Moisture and High-Traffic Areas

- UV Marble Sheets vs PVC Marble Sheets: Key Differences and Advantages

- FAQ