Essential Properties for Outdoor and Indoor Applications

Durability and Weather Resistance

Wood Plastic Composites, or WPC for short, stand out because they last longer and handle different weather conditions better than regular wood does. These materials are built to fight off problems that plague traditional wood products, like rotting over time, bending out of shape, or developing cracks. That's why people find them useful inside homes as well as outside on patios and decks. Some tests show that if installed correctly and looked after properly, WPC stuff can stick around for over 25 years before needing replacement. The toughness really matters outdoors where rain, sun, and changing temperatures wear down normal wood pretty fast. By switching to WPC instead, homeowners avoid dealing with those constant maintenance headaches. From building beautiful decks that don't warp to creating sound barriers that stay intact through seasons, WPC offers practical solutions without sacrificing appearance.

Eco-Friendly Material Composition

As people become more aware of environmental issues, the green benefits of WPC really stand out. These composite materials combine recycled wood fibers with plastic waste, making them a great option for those who care about sustainability. When compared to regular wood processing methods, WPC manufacturing typically produces fewer carbon emissions. This is why many green building projects incorporate WPC products. The Forest Stewardship Council (FSC) and similar organizations provide certification that confirms these materials come from responsibly managed sources. For individuals looking to cut down on their environmental footprint, or companies wanting to meet their ESG targets, WPC offers a practical solution. By using these composites instead of virgin wood products, we can help protect forests while finding new uses for plastic waste that would otherwise end up in landfills.

Low Maintenance Requirements

The fact that WPC needs so little maintenance is one big reason people pick it instead of regular wood these days. Wood usually requires constant sealing or painting just to keep looking decent and stop weather damage from setting in. With WPC, folks get something that stays attractive even if they don't spend hours on upkeep. The colors stay true and textures remain consistent across the board, so there's no need for those long maintenance sessions most wood owners dread. Homeowners report saving around 40 percent on their maintenance bills after switching to WPC materials according to various studies. And let's face it, who has time for all that extra work anyway? That's why many builders and property managers see WPC as not just convenient but actually smarter money wise for everything from backyard decks to hotel patios where ongoing maintenance would be a real headache.

Outdoor Wood Plastic Composite Applications

Decking and Patio Solutions

WPC makes great decking material because it doesn't get slippery when wet and stays cool even on hot days, so people can walk around safely barefoot outside. Homeowners love how versatile these composites are too. They can build decks that look just like real wood but still get all the benefits from plastic components mixed in there somewhere. Whether someone wants something rustic or super modern looking, WPC works well either way. Market trends show folks are buying more WPC products each year too. Experts predict about 6 percent annual growth rate for the next few years as more people discover what good stuff this actually is compared to other options available today.

Fencing and Railing Systems

WPC fencing gives great privacy and security without needing much maintenance like regular wood fences do. People who own homes have lots of color choices and different textures available so their fence matches whatever style they want outside. Plus, these fences stay strong and don't break down easily over time. More folks are switching to WPC instead of traditional materials because market research shows around 7 percent growth expected in WPC use for fences in coming years. Durable yet stylish, WPC fencing represents a good long term investment for yards today since it looks good and works well at the same time.

External Cladding and Facades

When used as exterior cladding, WPC offers real improvements in thermal insulation which helps buildings save on both heating bills and air conditioning expenses. Architects love working with this stuff because it can be shaped into all sorts of forms and looks modern when applied properly. We're seeing more commercial properties going this route lately, especially office complexes and retail spaces, since the material holds up well against weather damage and still looks good after years of exposure. The market seems to be trending toward wider acceptance of WPC cladding these days, partly because buildings stay looking fresh longer without needing constant maintenance. Plus there's that green angle too many developers care about nowadays.

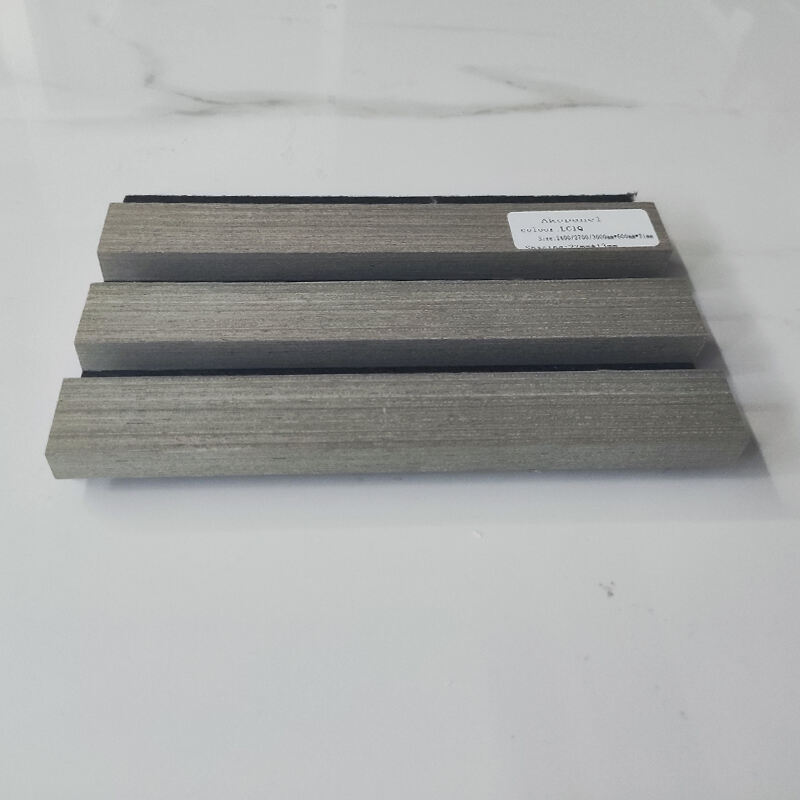

Acoustic and Decorative Wall Panels

Wood Plastic Composite or WPC materials are changing how we think about both sound absorption and decorative walls because they actually soak up noise pretty well. That makes them great choices when trying to create calm places across different environments. Think about office cubicles or living rooms where people want less background chatter. When these acoustic panels get installed properly, they really do help make spaces quieter and better suited for concentration or relaxation. There's also quite a variety of surface textures and color options now available, so designers can play around with things like those eye-catching three dimensional wall panels that definitely stand out from regular flat surfaces. Some tests indicate that good quality soundproofing can cut down unwanted noise by nearly half in particular situations, though results will vary depending on installation methods and room characteristics.

Moisture-Resistant Flooring

Waterproof composite (WPC) flooring is becoming increasingly popular in wet areas such as bathrooms and kitchens because it stands up well against water damage. Traditional wooden floors tend to warp and swell when exposed to moisture, but WPC materials resist these issues much better, which means they last longer with minimal upkeep. Many homeowners are drawn to WPC not just for its durability but also for how good it looks compared to regular laminate options. Industry reports indicate strong growth in WPC sales too, projecting around 5% annual increases moving forward. The market clearly shows people want flooring that handles spills and humidity while still looking great in their homes.

Modular Furniture and Cabinetry

WPC materials are gaining serious traction in the world of modular furniture and cabinet systems thanks to their strength combined with surprisingly low weight. People love these features because they enable all sorts of clever storage solutions that fit right into today's compact living spaces. Think about how apartment dwellers need every inch counted, or families wanting to rearrange rooms as kids grow up. Modular designs really shine here since they can be configured so many different ways depending on what fits best in any given room layout. Industry reports suggest the market for such furniture will expand around 8 percent within five years from now, mostly driven by widespread adoption of WPC across manufacturers. As homes continue shrinking while our stuff keeps growing, it's clear why this material has become such a big deal for folks looking for both practicality and eco-friendly alternatives at the same time.

Future Trends and Industry Innovations

Solar-Integrated Composites

Combining solar tech with wood plastic composite (WPC) materials represents something pretty exciting for the building industry these days. Scientists around the world are tinkering with ways to embed photovoltaic cells directly into WPC boards so they can actually produce electricity while still functioning as regular construction materials. Imagine decking that generates power or outdoor furniture that charges devices just sitting there in the sun. These developments fit right into what many countries are trying to achieve with their climate targets, pushing us toward buildings that don't just consume energy but maybe even contribute some back. Market analysts predict this niche could hit around half a billion dollars by 2030, which shows investors see potential here despite all the technical hurdles still needing work.

Advanced Texturing Techniques

New manufacturing techniques are pushing Wood Plastic Composites (WPC) to look better than ever before. Advanced production methods now let these composite materials copy the detailed grain patterns found in real wood pretty convincingly. This improved appearance makes WPC much more appealing to people who want the natural wood look but don't want to deal with all the upkeep issues or shorter lifespan of actual wood products. What's great is that WPC still keeps its core advantages like lasting longer and needing less care, so manufacturers can offer customers something that looks good while standing up to wear and tear. Market analysts see around 10% growth each year in demand for these textured WPC options, which shows they're becoming increasingly popular across various design projects nowadays.

Circular Economy Implementation

Shifting toward circular economy principles in the WPC industry has become key for boosting both sustainability and operational efficiency. Companies are rolling out creative recycling initiatives that recover old materials and give them new life, cutting down on industrial waste substantially. The focus on reuse rather than disposal means the entire sector is gradually becoming greener in practice. Industry reports suggest these circular approaches could boost market efficiency by around 15% over the next few years, showing how going green actually pays off financially as well as environmentally. As more businesses adopt these models, they find themselves gaining competitive advantages while doing their part for planet health.