Κατανόηση Πάνελ τοιχών PVC Ιδιότητες

Βασικά χαρακτηριστικά που επηρεάζουν τις ανάγκες συντήρησης

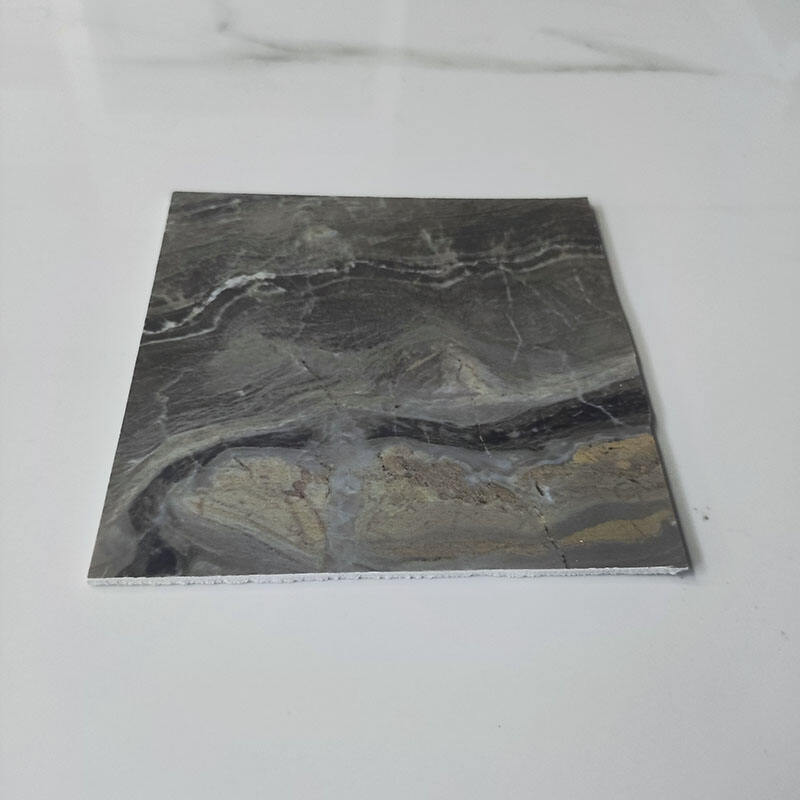

Τα πλακάκια PVC είναι πολύ αγαπημένα επειδή διαρκούν για πάντα, γεγονός που τα κάνει δημοφιλή σε πολλούς χώρους. Δεν τους νοιάζει καθόλου η υγρασία, έτσι οι τοίχοι του μπάνιου παραμένουν όμορφοι ακόμα κι όταν υπάρχει πολλή ατμός. Το ίδιο ισχύει και για τις κουζίνες όπου τα επίπεδα υγρασίας διαρκώς μεταβάλλονται. Αυτά τα πάνελ είναι επίσης πολύ χαμηλής συντήρησης, δεδομένου ότι το καθάρισμά τους συνήθως δεν απαιτεί τίποτα περισσότερο από το να αρπάξετε ένα πανί και να σκουπίσετε ό, τι ακαταστασία έχει συσσωρευτεί με την πάροδο του χρόνου. Κι άλλο μεγάλο πλεονέκτημα; Το PVC είναι πολύ ελαφρύ, οπότε η εγκατάσταση αυτών των πάνελ είναι πολύ πιο γρήγορη από ό, τι να ασχολείσαι με βαριά πράγματα όπως παραδοσιακά γύψο ή ξύλινα πλακάκια. Αυτό σημαίνει λιγότερη δουλειά για τους εργολάβους και ταχύτερα αποτελέσματα για τους ιδιοκτήτες ακινήτων. Επιπλέον, το γεγονός ότι το PVC δεν έχει πόρους εμποδίζει τα βακτήρια και τη μούχλα να αναπτυχθούν σε επιφάνειες, κάτι που τα νοσοκομεία και τα εστιατόρια εκτιμούν πολύ. Και μιλώντας για καθαρισμό, τα περισσότερα συνηθισμένα καθαριστικά λειτουργούν μια χαρά στο PVC χωρίς να προκαλούν ζημιά, οπότε κανείς δεν χρειάζεται να προμηθευτεί ακριβά ειδικά προϊόντα για τακτική συντήρηση.

Σύγκριση PVC με άλλα πάνελ τοίχου υλικά

Τα πλαίσια τοίχων PVC ξεχωρίζουν από τις παραδοσιακές επιλογές όπως το ξύλο ή το υψόπεδο κυρίως επειδή απαιτούν λιγότερη συντήρηση και διαρκούν περισσότερο. Το κανονικό ξύλο καταστρέφεται εύκολα από την υγρασία και τα παράσιτα, γεγονός που οδηγεί σε συνεχείς επισκευές και αντικαταστάσεις. Δεν είναι έτσι με τα πάνελ PVC που δεν νοιάζονται για το νερό ή τα έντομα. Γι' αυτό λειτουργούν τέλεια σε μέρη όπου η υγρασία είναι πάντα πρόβλημα. Η τιμή του PVC είναι επίσης υψηλότερη από τις ακριβότερες εναλλακτικές λύσεις όπως τα κεραμικά πλακάκια ή η πραγματική πέτρα. Οι εγκαταστάτες μπορούν επίσης να τα τοποθετήσουν πιο γρήγορα, εξοικονομώντας χρήματα σε κόστη εργασίας. Μελέτες δείχνουν ότι αυτά τα πλαστικά πάνελ συνήθως διαρκούν περισσότερο από πράγματα όπως το γύψο, πράγμα που σημαίνει ότι οι ιδιοκτήτες κτιρίων τα αντικαθιστούν λιγότερο συχνά και ξοδεύουν λιγότερα χρήματα συνολικά μακροπρόθεσμα. Οι περισσότεροι εργολάβοι προτείνουν να χρησιμοποιήσουν PVC για περιοχές που απαιτούν ελάχιστη συντήρηση, σκεφτείτε σχολεία και κουζίνες εστιατορίων όπου τα πληρώματα καθαρισμού μισούν να ασχολούνται με υλικά που απαιτούν συνεχώς προσοχή. Για τους διαχειριστές ακινήτων που επιθυμούν να μειώσουν το κόστος χωρίς να θυσιάσουν την ποιότητα, τα πάνελ PVC προσφέρουν τόσο πρακτικότητα όσο και φιλικά αποτελέσματα για το πορτοφόλι.

Καθημερινές και εβδομαδιαίες διαδικασίες καθαρισμού

Ασφαλείς λύσεις καθαρισμού για κοσμητικά πάνελ τοιχών

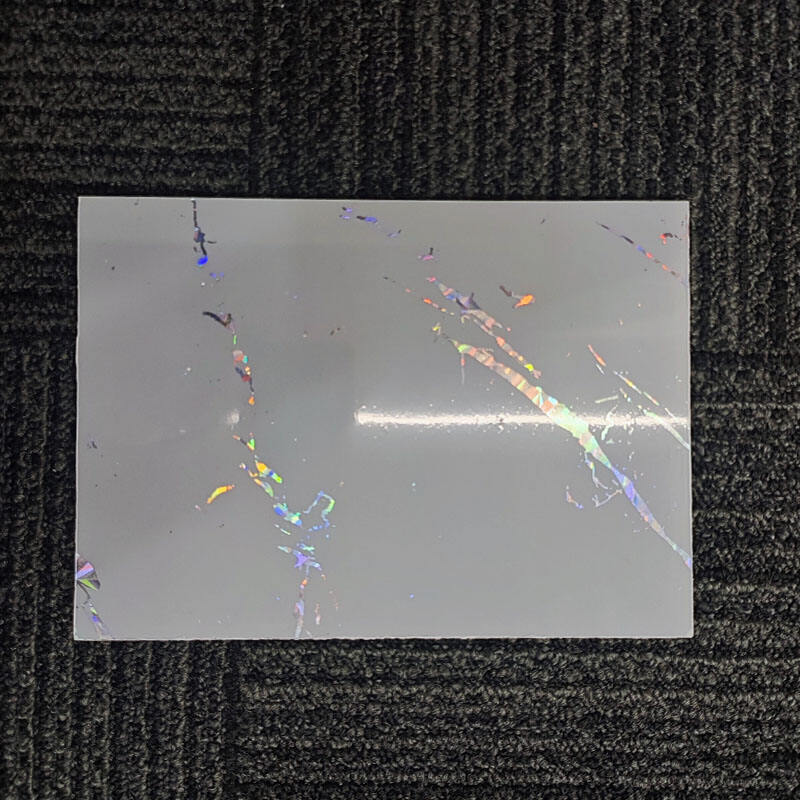

Για να διατηρούνται οι διακοσμητικές τοιχοποιίες όμορφες απαιτείται κάποια προσοχή στην επιλογή των προϊόντων καθαρισμού. Οι περισσότεροι άνθρωποι βρίσκουν ότι το συνηθισμένο σαπούνι πιάτων που αναμειγνύεται με ζεστό νερό λειτουργεί πολύ καλά για τις καθημερινές ανάγκες καθαρισμού. Υπάρχουν επίσης εμπορικά καθαριστικά ειδικά κατασκευασμένα για τοιχοειδή πλακάκια PVC που είναι διαθέσιμα στα hardware stores αν κάποιος προτιμά έτοιμες επιλογές. Το πλεονέκτημα αυτών των πιο απαλών προσεγγίσεων είναι ότι δεν αφήνουν υπολείμματα ή καταστρέφουν την επιφάνεια όπως μερικές φορές κάνουν τα ισχυρότερα χημικά καθαριστικά. Το να σκουπίζει κανείς γρήγορα μια φορά την εβδομάδα συνήθως εμποδίζει την συσσώρευση σκόνης και βρωμιάς, διατηρώντας έτσι την εμφάνιση και την καθαριότητα με την πάροδο του χρόνου. Δεν χρειάζεται όμως να φέρετε τα μπουκάλια - τείνουν να γρατζουνίζουν το λείο φινίρισμα και να κάνουν τα χρώματα να φαίνονται ξεθωριασμένα μετά από επανειλημμένη χρήση. Απλά κολλήστε με μαλακά υφάσματα και απαλές φόρμουλες για να διατηρήσετε αυτή τη φρέσκια, νέα εμφάνιση για χρόνια.

Τεχνικές για τις επιφάνειες πανελόπλακων με ακουστική μόνωση

Όταν πρόκειται για το καθαρισμό των ακουστικών πινάκων τοίχου, η απαλή χειραγώγηση είναι πολύ σημαντική αν θέλουμε να κρατήσουμε τα χαρακτηριστικά ηχομόνωσης άθικτα. Για τακτική απομάκρυνση σκόνης, χρησιμοποιήστε κάτι μαλακό όπως ένα πανί μικροϊνών αντί για κάτι με άκαμπτες τρίχες που μπορεί να βλάψουν την απορρόφηση ήχου από τα πάνελ. Το καθαρισμό των σημείων έχει επίσης νόημα όταν πρόκειται για ακατασταλμένα πράγματα, ειδικά επειδή υπάρχουν ειδικά σχεδιασμένα καθαριστικά αφρού που αντιμετωπίζουν τις λεκέδες χωρίς να επηρεάζουν την ικανότητα του πάνελ να λειτουργεί σωστά. Το νερό είναι σίγουρα απαγορευμένο εδώ, αν και το νερό που μπαίνει μέσα μπορεί να περάσει κρυφά από τις ραφές και να μειώσει σοβαρά την αποτελεσματικότητά τους στην αποκάλυψη θορύβου. Η σωστή συντήρηση σημαίνει ότι αυτά τα πάνελ θα συνεχίσουν να κάνουν αυτό που υποτίθεται ότι πρέπει να κάνουν για τα επόμενα χρόνια.

Λάθη που πρέπει να αποφεύγονται σε περιοχές με υψηλή υγρασία

Όταν καθαρίζετε τα πάνελ PVC σε μέρη όπου υπάρχει πολλή υγρασία όπως μπάνια και κουζίνες, υπάρχουν μερικά κοινά λάθη που οι άνθρωποι τείνουν να κάνουν. Πολλοί άνθρωποι δεν συνειδητοποιούν ότι η χρήση κανονικών καθαριστικών στο σπίτι σε PVC μπορεί να φθείρει το υλικό με την πάροδο του χρόνου. Να χρησιμοποιείτε καθαριστικά ειδικά για επιφάνειες PVC για να τα κρατάτε όμορφα για χρόνια. Η καλή κυκλοφορία αέρα γύρω από τα πάνελ είναι επίσης σημαντική επειδή χωρίς αυτήν, η μούχλα και η μούχλα μπορούν να αρχίσουν να αναπτύσσονται πίσω από τα πάνελ, κάνοντάς τα να φαίνονται άσχημα και αποδυναμώνοντας τη δομή τους. Μην ξεχάσετε να ελέγχετε τα κενά μεταξύ των πάνελ τακτικά για τυχόν σημάδια νερού που περνάει. Έχουμε δει περιπτώσεις όπου η διαρροή νερού πέρασε απαρατήρητη μέχρι να προκληθεί σοβαρή ζημιά. Η τήρηση αυτών των βασικών συμβουλών συντήρησης συμβάλλει στη διασφάλιση της αποτελεσματικότητας και της ελκυστικότητας των πλακών PVC ακόμη και σε συνεχώς υγρό περιβάλλον.

Προηγμένη συντήρηση για μακροχρόνια διατήρηση

Προληπτικά μέτρα για περιοχές με έντονη κυκλοφορία

Οι τοίχοι σε μέρη όπου περπατούν πολλοί άνθρωποι δείχνουν γρήγορα σημάδια φθοράς. Τοποθετώντας ελαστικές γωνιακές προστασίες γύρω από τις πόρτες και κατά μήκος των τοίχων, γίνεται μεγάλη διαφορά για να μην υπάρχουν αυτές οι ενοχλητικές γρατζουνιές. Το έχουμε δει να λειτουργεί ιδιαίτερα καλά σε κτίρια γραφείων και σχολεία όπου τα παιδιά τρέχουν όλη μέρα. Μην ξεχάσεις να ελέγχεις τακτικά και αυτά τα σημεία. Μια γρήγορη ματιά τώρα και μετά πιάνει μικρές μπουκάλες πριν μετατραπούν σε μεγαλύτερα προβλήματα από συνεχές χτύπημα. Για επιπλέον προστασία, πολλές εγκαταστάσεις εφαρμόζουν ειδικές επικάλυψεις στους πίνακες PVC. Αυτά τα επιχρίσματα λειτουργούν ως θωράκιση ενάντια στις καθημερινές ραφές και βοηθούν τα πάνελ να διαρκούν περισσότερο χωρίς να φαίνονται φθαρμένα. Το αποτέλεσμα; Καθαρότεροι τοίχοι, ακόμα και μετά από χρόνια βαριάς κυκλοφορίας.

Επισκευή χαρακιών και ζημιών στην επιφάνεια

Η αντιμετώπιση γρατζουνιών και άλλων επιφανειακών βλαβών σε τοίχους χρειάζεται κάποιες έξυπνες προσεγγίσεις αν θέλουμε να φαίνονται καλά και να λειτουργούν σωστά. Οι μικρές γρατζουνιές συνήθως ανταποκρίνονται καλά στο γυαλί με τα προϊόντα επισκευής PVC που τα περισσότερα hardware store έχουν σήμερα. Όταν όμως αντιμετωπίζουν μεγαλύτερες οπές, οι άνθρωποι συχνά στρέφονται σε ενσωματώσεις ή επιδέσμους που διορθώνουν τα πράγματα χωρίς να χρειάζεται να αντικατασταθούν ολόκληρα τμήματα. Πραγματικά ωφελεί να έχεις κοντά σου ένα βασικό κιτ συντήρησης για αυτές τις μικρές δουλειές. Αυτό όχι μόνο εξοικονομεί χρήματα μακροπρόθεσμα, αλλά σημαίνει επίσης λιγότερα ταξίδια στο κατάστημα και λιγότερες εντάσεις συνολικά όταν προσπαθούμε να κρατήσουμε αυτά τα τοίχωμα τα καλύτερα.

Προστατευτικές Επεξεργασίες για Πάνελ Εκτεθειμένα στον Ήλιο

Τα τοίχωμα που εκτίθενται σε πολύ ήλιο τείνουν να εξασθενούν και να σπάσουν με την πάροδο του χρόνου, πράγμα που σημαίνει ότι χρειάζονται κάποια προστασία τελικά. Ένας καλός τρόπος για να το καταπολεμήσουμε είναι να εφαρμόσουμε τις ανθεκτικές στις υπεριώδεις ακτίνες επιχρίσεις που πωλούνται στα εργαστήρια σήμερα. Κάνουν θαύματα για να κρατούν τα πάνελ φρέσκα για περισσότερο καιρό. Το να ελέγχετε τακτικά τους τοίχους είναι επίσης λογικό, επειδή το να εντοπίσετε τα προβλήματα νωρίς εξοικονομεί χρήματα στο μέλλον. Προσέξτε για τα σημεία όπου το χρώμα αρχίζει να θολώνει ή η υφή αλλάζει ελαφρώς. Και μην ξεχάσεις τα παράθυρα! Η προσθήκη τεντωμάτων ή κουρτίνων δημιουργεί ένα απόφραγμα μεταξύ του σκληρού ηλιακού φωτός και των ίδιων των πάνελ. Αυτό το απλό βήμα στην πραγματικότητα εμποδίζει τον ήλιο να κάνει τόση ζημιά, κάνοντας τα πάντα να διαρκούν χρόνια περισσότερο από ό, τι οι περισσότεροι άνθρωποι περιμένουν.

Στρατηγικές Προστασίας Περιβάλλοντος

Έλεγχος υγρασίας για αντηχητικές πλάκες

Η υγρασία εσωτερικού χώρου είναι πραγματικά σημαντική όσον αφορά τη διατήρηση πλαίσια ηχοάπογισης σε καλή κατάσταση με την πάροδο του χρόνου. Οι περισσότεροι ειδικοί προτείνουν να στοχεύετε σε υγρασία περίπου 40 έως 60 τοις εκατό για να αποτρέπονται εκείνα τα ενοχλητικά προβλήματα, όπως η παραμόρφωση ή η καταστροφή. Τα πάνελ παραμένουν δομικά σταθερά μέσα σε αυτό το εύρος και λειτουργούν καλύτερα και στην απόρριψη θορύβου. Για χώρους όπου υπάρχει τάση για επιπλέον υγρασία, η απόκτηση ενός αξιόπιστου αφυγραντήρα κάνει τη διαφορά. Αυτές οι μηχανές διατηρούν τα πράγματα από το να γίνουν πολύ υγρά, έτσι τα πάνελ δεν υφίστανται περιττή πίεση. Και μην ξεχνάτε να ελέγχετε τα επίπεδα υγρασίας τώρα και τότε με κατάλληλα όργανα μέτρησης. Η έγκαιρη ανίχνευση προβλημάτων σημαίνει ότι μπορούν να διορθωθούν πριν μετατραπούν σε μεγαλύτερα προβλήματα αργότερα, κάτι που βοηθά στη διατήρηση της αποτελεσματικότητας των πάνελ.

Θερμοκρασιακές Διακυμάνσεις

Οι αλλαγές θερμοκρασίας έχουν μεγάλη επίδραση στην απόδοση και την εμφάνιση των πλακών PVC με την πάροδο του χρόνου. Όταν τα τοποθετείς, βοηθάει πολύ αν τοποθετηθούν κάπου όπου η θερμοκρασία παραμένει σταθερή. Οι ακραίες θερμοκρασίες είναι άσχημα νέα για αυτά τα πάνελ επειδή τείνουν να επεκτείνονται όταν είναι ζεστά και να συρρικνώνονται όταν είναι κρύα, και αυτή η κίνηση μπρος-πίσω μπορεί να κάνει τις ραφές μεταξύ των πάνελ να αρχίσουν να χωρίζονται. Ένας καλός τρόπος για να ξεπεράσουμε αυτό το πρόβλημα; Η θερμική μόνωση κάνει θαύματα, ειδικά σε μέρη που είναι γνωστά για τις άγριες διακυμάνσεις της θερμοκρασίας. Η μόνωση όχι μόνο προστατεύει από ζημιές, αλλά επίσης καθιστά τους πίνακες πιο ανθεκτικούς και λειτουργούν καλύτερα μακροπρόθεσμα.

Σημεία Ελέγχου Εποχιακής Επιθεώρησης

Το να ρυθμίζετε τακτικούς ελέγχους των οροφικών πάνελ κάθε έξι μήνες περίπου βοηθά να εντοπίσετε τα προβλήματα νωρίς πριν μετατραπούν σε μεγάλες επισκευές στο μέλλον. Όταν κάνετε αυτές τις επιθεωρήσεις, να προσέχετε για πράγματα όπως το σχηματισμό κηλίδων, το νερό που περνάει μέσα από ρωγμές και γενικές ζημιές που συσσωρεύονται με την πάροδο του χρόνου. Τα προβλήματα αυτά μπορεί να μην φαίνονται σοβαρά με την πρώτη ματιά, αλλά μπορούν πραγματικά να αποδυναμώσουν την δομική αντοχή των πάνελ. Το να κρατάτε αρχεία για το τι παρατηρείται κατά τη διάρκεια κάθε ελέγχου αποδεικνύεται πολύτιμο μακροπρόθεσμα. Οι σημειώσεις βοηθούν να θυμόμαστε πού συνέβησαν προβλήματα στο παρελθόν και τι είδους συντήρηση ήταν καλύτερη εκεί, κάνοντας ευκολότερο τον προγραμματισμό μελλοντικής φροντίδας και την παράταση της διάρκειας ζωής αυτών των πινάκων χωρίς απροσδόκητες βλάβες.

Πίνακας Περιεχομένων

- Κατανόηση Πάνελ τοιχών PVC Ιδιότητες

- Βασικά χαρακτηριστικά που επηρεάζουν τις ανάγκες συντήρησης

- Σύγκριση PVC με άλλα πάνελ τοίχου υλικά

- Καθημερινές και εβδομαδιαίες διαδικασίες καθαρισμού

- Ασφαλείς λύσεις καθαρισμού για κοσμητικά πάνελ τοιχών

- Τεχνικές για τις επιφάνειες πανελόπλακων με ακουστική μόνωση

- Λάθη που πρέπει να αποφεύγονται σε περιοχές με υψηλή υγρασία

- Προηγμένη συντήρηση για μακροχρόνια διατήρηση

- Προληπτικά μέτρα για περιοχές με έντονη κυκλοφορία

- Επισκευή χαρακιών και ζημιών στην επιφάνεια

- Προστατευτικές Επεξεργασίες για Πάνελ Εκτεθειμένα στον Ήλιο

- Στρατηγικές Προστασίας Περιβάλλοντος

- Έλεγχος υγρασίας για αντηχητικές πλάκες

- Θερμοκρασιακές Διακυμάνσεις

- Σημεία Ελέγχου Εποχιακής Επιθεώρησης