Vantagens Chave que Impulsionam Painel de Parede WPC Popularidade

Material de Construção Ecológico

Painéis de parede WPC, feitos a partir de composto de Plástico e Madeira , tornaram-se bastante populares ultimamente devido à forma como são fabricados. O material é basicamente composto por resíduos de madeira misturados com plástico reciclado, reduzindo assim a necessidade de utilizar nova madeira proveniente de árvores. Isso ajuda a preservar nossas florestas por períodos mais longos. Profissionais da construção que se preocupam com práticas sustentáveis apreciam esse material, pois reduz o impacto ambiental em diversos aspectos. Além disso, é interessante notar que a fabricação desses painéis geralmente consome menos energia do que a produção de alternativas convencionais. Para qualquer pessoa envolvida em projetos de construção nos dias de hoje, onde a sustentabilidade é uma prioridade, optar por painéis WPC faz sentido tanto do ponto de vista ecológico quanto econômico. Muitos empreiteiros relatam melhores resultados ao trabalhar com esses painéis em comparação com as opções tradicionais, atendendo ainda às novas regulamentações sobre construção sustentável.

Durabilidade Contra Umidade e Pragas

Os painéis de parede de WPC resistem muito bem à umidade e às pragas, o que explica porque se tornaram tão populares ultimamente. Estes painéis foram concebidos para combater danos causados pela água, para não ficarem apodrecidos ou com mofo como os painéis de madeira normais. E como os insetos também não gostam de mastigá-los, os proprietários poupam dinheiro em reparos futuros. Estudos mostram que os painéis de WPC normalmente duram muito mais do que a madeira simples quando expostos a condições difíceis ao ar livre. Para pessoas que vivem em locais com muitos problemas de chuva ou umidade, ou que lidam com problemas de cupins, o WPC faz todo o sentido. Continuam a trabalhar sem necessitar de atenção constante, mesmo depois de anos de exposição a tudo o que a Mãe Natureza lhes lança.

Baixo requisito de manutenção

Os painéis de parede de WPC realmente se destacam quando se olha para os requisitos de manutenção. A madeira tradicional precisa de atenção constante com trabalhos regulares de pintura e vedação, mas estes painéis compostos simplesmente ficam lá sem muita confusão. É por isso que tantos proprietários e empresários se sentem atraídos por eles, especialmente porque ninguém quer gastar horas em manutenção ou pagar grandes cheques por trabalhos de manutenção. A superfície lisa do WPC torna a limpeza simples, o que é muito importante em locais como restaurantes ou centros de saúde onde os germes são uma preocupação constante. Os administradores de imóveis vão notar uma economia de dinheiro real ao longo do tempo porque há tão pouca manutenção necessária ao longo da vida destes painéis. Para quem quer que tente equilibrar materiais de qualidade com restrições orçamentárias, a WPC oferece uma solução inteligente que continua a ser boa ano após ano.

Flexibilidade do projeto e apelo estético

Os painéis de parede de WPC trazem muita liberdade de design e ficam ótimos em edifícios. Estes painéis têm todo o tipo de texturas diferentes, desde superfícies lisas até àquelas que imitam grãos de madeira, além de um arco-íris de cores disponível. Quer alguém queira algo clássico ou super moderno, estes painéis funcionam surpreendentemente bem para ambos os estilos. Alguns fabricantes têm sido bastante criativos ultimamente com os seus métodos de produção, fazendo painéis de parede 3D que realmente chamam a atenção quando instalados. A combinação de ser bonito e prático é a razão pela qual tantos designers gravitam para o WPC para seus projetos. Os arquitetos adoram saber que podem obter paredes que não só resistem ao desgaste, mas também fazem um espaço parecer especial visualmente.

Inovações Tecnológicas nos Painéis de Parede WPC

Painéis com Melhorias Acústicas e de Isolamento Sonoro

A tecnologia WPC evoluiu bastante nos últimos anos, resultando em painéis acústicos que funcionam muito bem no bloqueio de ruído. Hoje em dia, os painéis de WPC podem resistir aos materiais tradicionais de isolamento acústico quando se trata de reduzir os níveis de ruído, o que significa que as pessoas dentro dos edifícios experimentam muito menos perturbações externas. O que torna estes painéis interessantes é a forma como combinam diferentes materiais que aumentam as suas propriedades de absorção de som, enquanto ainda se mostram bem nas paredes. É por isso que as vemos aparecer em todo o lado, desde escritórios domésticos até salas de conferências em edifícios corporativos. Os fabricantes continuam a melhorar estes produtos porque há uma demanda clara por melhores ambientes de som sem comprometer a aparência.

Recursos Avançados de Resistência ao Fogo

Os últimos desenvolvimentos na tecnologia WPC tornaram estes painéis muito mais resistentes ao fogo, cumprindo as regras de segurança contra incêndio em diferentes áreas. Para os gestores de imóveis que procuram materiais de construção melhores, isto significa que os seus investimentos são mais seguros. Os testes de laboratório mostram que os painéis de WPC não ajudam a espalhar incêndios quando as coisas dão errado, por isso os edifícios com eles dentro são geralmente lugares mais seguros. Com o bom desempenho que apresentam sob estresse térmico, muitos arquitetos agora especificam WPC para projetos que vão desde complexos de apartamentos a edifícios de escritórios, onde a segurança contra incêndio é sempre uma preocupação principal.

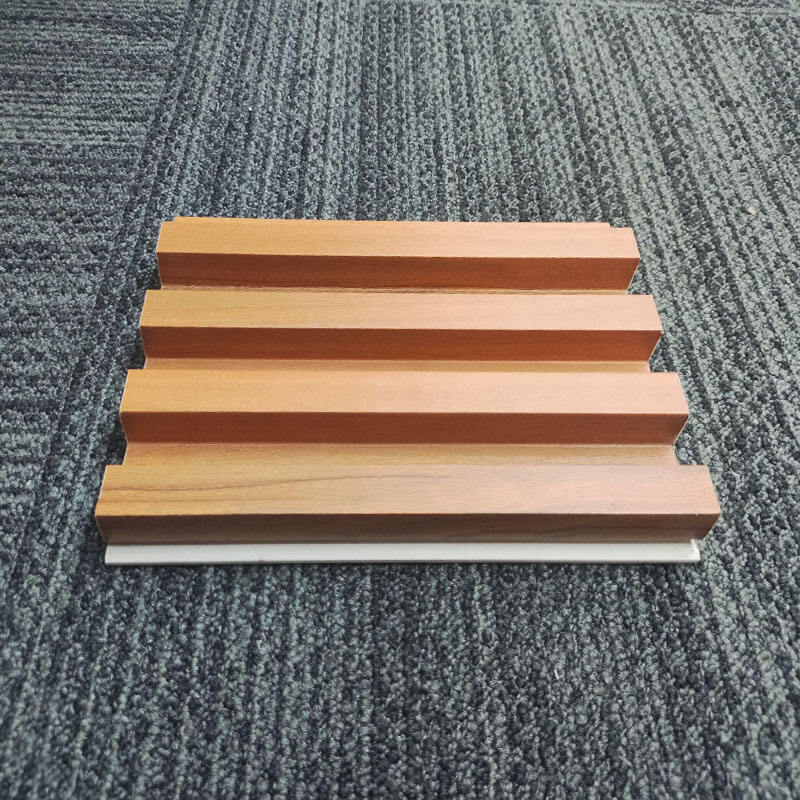

3D Wall Panel Designs

Os painéis tridimensionais de parede feitos de compósitos de madeira plástica (WPC) estão a mudar a forma como pensamos sobre espaços interiores, com toneladas de possibilidades de design que funcionam muito bem em escritórios, lojas e casas. Arquitetos e designers de interiores adoram-nos porque conseguem criar looks realmente únicos que chamam a atenção e fazem os quartos se destacar visualmente. O próprio material é surpreendentemente leve, mas ainda assim suficientemente forte para suportar essas formas 3D complexas sem problemas. Os instaladores acham que é muito mais fácil de manusear do que os materiais tradicionais, mantendo toda a resistência necessária para uso a longo prazo. Vimos esta tendência aumentar nos últimos anos, à medida que os fabricantes continuam a melhorar os seus produtos. Estes painéis estão agora a aparecer em todo o lado, desde restaurantes da moda até apartamentos de luxo, e muitos especialistas acreditam que vão tornar-se padrão na arquitetura contemporânea no futuro.

Melhorias Estruturais Leves

Novos métodos de fabricação permitiram produzir painéis de parede de WPC leves, que reduzem tanto o tempo de instalação quanto os custos de transporte. O interessante é que, apesar de serem mais leves, estes painéis mantêm uma sólida integridade estrutural, o que atrai os empreiteiros que procuram algo fácil de trabalhar, mas ainda durável o suficiente para projetos de construção reais. O peso reduzido significa também menos consumo de combustível durante o transporte, o que se encaixa bem nas normas e regulamentos de construção ecológica em vigor em muitas regiões. Estamos a ver esta tendência a ganhar força entre os empreiteiros comerciais, em particular, uma vez que pesquisas recentes mostram que mais de 60% dos novos projectos de construção agora especificam alguma forma de material composto leve devido a estas vantagens práticas e ambientais combinadas.

Liderança do Mercado Consolidado na América do Norte

No que respeita aos painéis de parede de madeira plástica composta (WPC), a América do Norte continua a estar na vanguarda, principalmente devido às bases de fabrico bem estabelecidas e aos desenvolvimentos tecnológicos de ponta. Empresas de construção em todo o continente estão se afastando dos materiais tradicionais em direção a opções mais ecológicas, tornando os WPCs cada vez mais populares nos últimos anos. Os Estados Unidos desempenham um papel importante aqui, representando uma grande parte de todo o uso de WPC em todo o país. Esta dominação também se mostra em números A América do Norte controla cerca de 39,3 por cento do mercado mundial, trazendo cerca de 3,1 bilhões de dólares anualmente. Estas estatísticas realçam o compromisso desta região em manter-se à frente na corrida para soluções de construção sustentáveis.

Explosão de Urbanização Rápida na Ásia-Pacífico

A urbanização está a descolar na região Ásia-Pacífico, criando uma enorme necessidade de soluções de construção a preços acessíveis como os produtos WPC. Com as economias crescendo rapidamente e as pessoas ganhando mais dinheiro hoje em dia, a atividade de construção só continua a acelerar. Estamos a ver o WPC a ser usado em todo o lado, desde projectos residenciais até a construção comercial na área. Os analistas de mercado prevêem um forte crescimento contínuo da WPC na Ásia nos próximos anos. Os governos de países como a China e a Índia estão a investir em infraestruturas e a promover alternativas mais ecológicas. Estas forças gêmeas de investimento e consciência ambiental estão a impulsionar o mercado, tornando a Ásia-Pacífico uma das regiões mais interessantes para os fabricantes de compósitos de madeira e plástico neste momento.

Regulamentações de Sustentabilidade na Europa

Regras de sustentabilidade rigorosas estão a modelar a forma como os negócios funcionam na Europa neste momento, e estão a empurrar as empresas para opções mais ecológicas como os produtos de WPC. Tomemos, por exemplo, os painéis de parede de WPC, que se encaixam muito bem no que a UE quer alcançar através da sua iniciativa Green Deal, uma vez que reduzem as emissões de carbono durante os projectos de construção. Além disso, há todo o tipo de benefícios financeiros dos governos que incentivam as pessoas a mudar para estes painéis, tornando-os atraentes não só para casas, mas também para grandes empreendimentos comerciais. Com tanto foco em tornar-se verde nos círculos de construção ultimamente, os benefícios do WPC se destacam porque não prejudica o ambiente tanto quanto os materiais tradicionais. Os construtores e os promotores de imóveis também estão a começar a ver isto, o que explica porque continuamos a ver mais instalações de WPC a surgir em mercados onde as regulamentações desempenham um papel tão importante na tomada de decisões.

Aplicações que Transformam as Práticas de Construção

Residencial: Soluções Habitacionais Economicamente Viáveis

Os painéis de parede compostos de madeira e plástico estão a mudar a forma como construímos as nossas casas hoje, porque oferecem um bom valor sem comprometer a aparência ou a qualidade. Os construtores acham que esses painéis são muito úteis quando tentam reduzir o tempo gasto na construção de casas. Alguns projetos do mundo real mostram que o uso de WPC pode economizar dinheiro em custos de mão-de-obra, uma vez que a instalação é muito mais rápida do que os métodos tradicionais. A flexibilidade do projeto do WPC significa que funciona bem em diferentes tipos de situações habitacionais também. Quer alguém queira renovar um pequeno apartamento da cidade ou construir uma casa de família grande nos subúrbios, provavelmente há uma opção de WPC disponível. Os proprietários de casas que querem ter algo que pareça ótimo, mas que não faça o banco cair, muitas vezes recorrem a produtos de WPC para seu próximo projeto.

Espaços Comerciais: Demanda por Painéis Acústicos de Parede

Os espaços comerciais estão a ver uma procura cada vez maior de painéis acústicos ultimamente porque as empresas precisam realmente de um melhor controlo de som. Os painéis de parede de WPC tornaram-se praticamente padrão em escritórios abertos onde as pessoas lutam com ruídos constantes de colegas de trabalho e equipamentos. Estes painéis ajudam os trabalhadores a concentrarem-se mais, uma vez que reduzem as distrações que perturbam a concentração. Os dados imobiliários mostram que os proprietários começam a instalar estes materiais em novas construções e reformas. As empresas agora entendem que os funcionários têm melhor desempenho quando o espaço de trabalho não está constantemente cheio de conversa e sons de máquinas. O que faz os painéis de WPC se destacar é como eles fazem duas coisas ao mesmo tempo, isolamento sonoro e também boa aparência. Esta combinação explica por que tantos arquitetos as especificam para projetos de escritórios modernos hoje em dia.

Industrial: Revestimento Resistente ao Tempo

Os painéis de parede de WPC funcionam muito bem como revestimento em ambientes industriais onde os edifícios enfrentam condições climáticas difíceis durante todo o ano. Estes painéis resistem muito bem a coisas como ferrugem, danos causados pela água e exposição ao sol o que significa que duram muito mais do que os materiais tradicionais quando instalados no exterior. Algumas fábricas que mudaram para painéis de WPC notaram que suas contas de reparo diminuíram bastante ao longo do tempo. O dinheiro economizado em reparos constantes aumenta rapidamente, especialmente considerando a frequência com que essas estruturas precisam de cuidados. Para empresas que olham para os seus resultados, mas que ainda querem algo durável o suficiente para lidar com o que a Mãe Natureza lhe lança, os painéis de WPC parecem uma escolha inteligente para manter a infraestrutura intacta sem quebrar o banco na manutenção.

Sumário

- Vantagens Chave que Impulsionam Painel de Parede WPC Popularidade

- Inovações Tecnológicas nos Painéis de Parede WPC

- Liderança do Mercado Consolidado na América do Norte

- Explosão de Urbanização Rápida na Ásia-Pacífico

- Regulamentações de Sustentabilidade na Europa

- Aplicações que Transformam as Práticas de Construção