What Is a WPC Wall Panel? Composition, Core Types, and Key Performance Metrics

WPC (Wood-Plastic Composite) wall panels fuse natural wood fibers with thermoplastic polymers—delivering authentic wood aesthetics with superior durability, dimensional stability, and moisture resistance compared to solid wood or MDF.

Wood Fiber, Thermoplastics, and Additives: How Material Ratios Impact Durability and Moisture Resistance

Precision in formulation defines real-world performance. Typical WPC wall panels contain:

- Wood fiber (50–70%): Supplies rigidity, texture, and thermal mass.

- Thermoplastics—primarily PVC or PP (30–50%): Provide water impermeability and thermal resilience.

- Additives (<10%): Including UV stabilizers, calcium zinc (for microbial resistance), and halogen-free flame retardants.

Higher wood content enhances stiffness but increases hygroscopic risk; panels with ≥55% thermoplastics consistently achieve water absorption <0.8%—a benchmark validated by ASTM D7031 testing for 100% humidity endurance. Balanced blends limit post-immersion swelling to under 0.5%, preventing warping in humid climates (Material Flexibility Study 2023).

Solid vs. Hollow Core, Fire Ratings (Class B1), and Tongue-and-Groove Precision

Core construction determines weight, acoustic behavior, and application suitability:

| Feature | Solid Core | Hollow Core |

|---|---|---|

| Weight | 5.3 kg/m² | 4.1 kg/m² |

| Best For | High-impact commercial zones | Cost-conscious residential projects |

| Sound Insulation | Superior (25 dB reduction) | Moderate (18 dB reduction) |

Both core types meet Class B1 fire rating—self-extinguishing within 10 seconds of flame removal—thanks to integrated flame-retardant additives. Precision-machined tongue-and-groove edges ensure seamless alignment, cutting moisture infiltration risk by 70% versus butt-jointed systems.

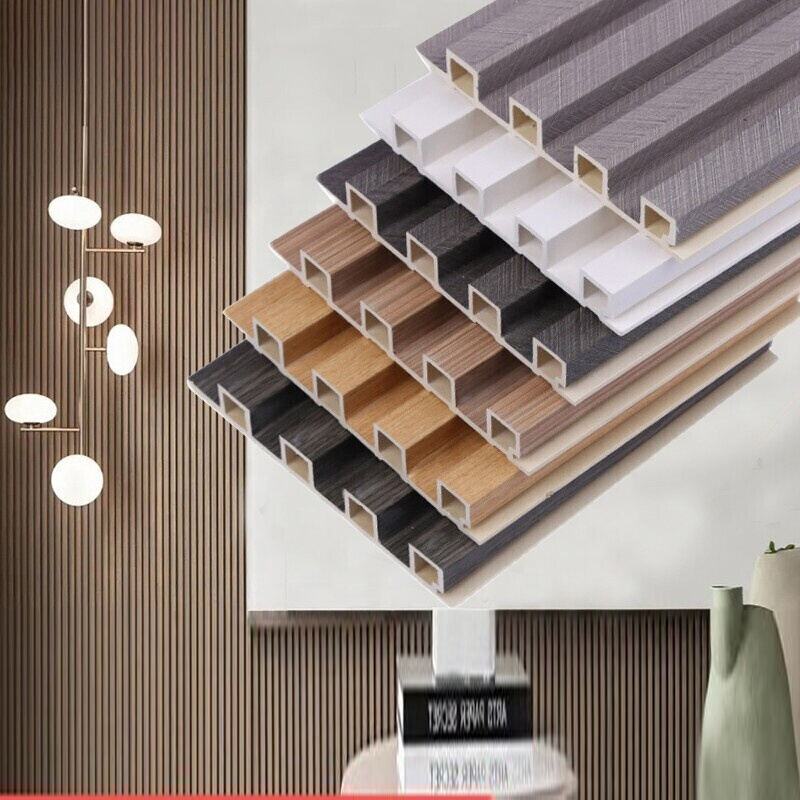

WPC Wall Panel Aesthetics: Finishes, Textures, and Interior Design Compatibility

Fluted, Slat, 3D, Marble, and Metallic Options — Matching WPC Wall Panel Styles to Modern Residential Spaces

WPC wall panels manage to combine bold design ideas with practical performance requirements. The fluted designs bring rhythm and create a sense of height in simple interior spaces. Slat patterns add a warm, natural feel that works really well in family areas and private bedrooms. For those wanting something more dramatic, 3D textured panels can transform plain entryways into striking features or give media walls extra dimension. Marble effect finishes look just like real stone but don't require any special maintenance like sealing or worrying about acid etching. And then there are the metallic options too, think brushed gold or matte silver surfaces that bring an industrial edge to kitchen spaces and work areas throughout the home.

Most designs keep their colors looking good even when exposed to sunlight and moisture because they're built with special UV resistant coatings and minerals that help them hold up over time. The way these products install together creates straight lines between pieces which is really important when covering big areas since crooked joints just look bad from a distance. How lighting affects appearance cannot be ignored either. Light colored panels can make small spaces feel bigger, something designers often use in tight apartments or offices. Darker tones on the other hand tend to create a cozy atmosphere, making people feel more at home. That's why neutral gray tones and soft white shades continue to be popular picks among professionals who need materials that will still work well years down the road as trends change.

Functional Prioritization: Matching WPC Wall Panel Properties to Room-Specific Demands

High-Moisture Zones: Why Kitchens and Bathrooms Require Premium Water-Resistant WPC Wall Panels

In kitchens and bathrooms, basic water resistance just isn't enough anymore. These spaces need real protection against constant humidity and those inevitable splashes that happen daily. Standard building materials start to break down once they absorb more than about 5% moisture. But premium WPC panels made with at least 60% high density thermoplastic plus special calcium zinc additives bring absorption down to less than half a percent. That makes all the difference for preventing mold growth, keeping surfaces from peeling apart, and maintaining their strength year after year. When dealing with areas where water is always present, look for panels that meet ASTM D7031 standards and have those sealed tongue and groove connections. Contractors who've worked on similar projects swear by these features since they hold up even when exposed to full humidity conditions day in and day out.

Sound-Sensitive Areas: Acoustic-Grade WPC Wall Panels for Living Rooms and Home Offices

Noise levels around 45 to 50 decibels can really mess with comfort and focus in spaces like living rooms and home offices when going through regular drywall. Acoustic quality WPC panels tackle this problem by using either hollow core designs or adding mineral wool inside them to soak up sound waves. These panels cut down on air borne noise by roughly 30 to 35 decibels. The surface matters too. Textures such as fluted patterns or three dimensional reliefs help spread out reflected sounds rather than letting them bounce back directly. This results in Noise Reduction Coefficients reaching about 0.8 which is pretty good for most applications. When shopping for these panels, check for products with Class A acoustic ratings and surfaces that resist impacts so they keep working well even after years of normal wear and tear while still looking great in any interior space.

Installation, Maintenance, and Real-World Longevity of WPC Wall Panels

DIY Installation Best Practices, Substrate Prep, and Avoiding Common Mistakes with WPC Wall Panels

Start with a clean, dry, and level substrate—surface deviations 3 mm can induce panel stress and visible waviness. In moisture-prone areas, install a vapor barrier beneath the substrate to prevent trapped humidity. During assembly:

- Leave 5–10 mm expansion gaps at perimeters and between panels to accommodate thermal movement (omitting these is the leading cause of buckling).

- Use corrosion-resistant fasteners spaced 30–40 cm apart, driven flush—not over-tightened—to avoid dimpling or cracking.

- Confirm alignment every third row using a laser level, especially with directional patterns like slats or flutes.

Three common mistakes happen all the time when working with these panels: not making pilot holes first which can cause wood to split, rushing installation before letting them sit for at least 48 hours to adjust to room conditions, and getting the tongue and groove joints wrong. When it comes to cleaning, stick to regular monthly wipe downs using just plain old pH neutral soap and a gentle microfiber cloth. Stay away from anything scratchy or harsh chemicals since they'll eat away at those protective UV coatings over time. Don't forget to check those edge seals once a year too. Small scratches or marks aren't the end of the world though - there are some good silicone based repair kits out there that work surprisingly well. Most people find their WPC wall panels last way beyond expectations, often staying strong and looking great for around 25 years or more, even in bathrooms or kitchens where other materials tend to warp or rot after just a few years.

FAQ Section

What does WPC stand for?

WPC stands for Wood-Plastic Composite, which is a material made from wood fibers and thermoplastic polymers.

Are WPC panels waterproof?

WPC panels offer exceptional water resistance, with premium panels achieving water absorption rates of less than half a percent, making them suitable for areas with high humidity.

How long can WPC panels last?

WPC panels are known for their durability and can last over 25 years even in moisture-prone areas like kitchens and bathrooms.

Table of Contents

- What Is a WPC Wall Panel? Composition, Core Types, and Key Performance Metrics

- WPC Wall Panel Aesthetics: Finishes, Textures, and Interior Design Compatibility

- Functional Prioritization: Matching WPC Wall Panel Properties to Room-Specific Demands

- Installation, Maintenance, and Real-World Longevity of WPC Wall Panels

- FAQ Section