Superior Moisture Resistance of PVC Panels

How the Non-Porous Surface Prevents Water Absorption

When it comes to wet areas, PVC panels really shine compared to older materials because they're made of polymers that don't let water through. Traditional options such as drywall or wooden boards absorb moisture easily, but PVC panels only take in between 0.01 and 0.1 percent water when tested according to those ASTM D570 guidelines. That means no swelling issues or damage to the structure over time. The reason for this waterproof quality lies in how the molecules link together at a microscopic level. Researchers who study plastics have confirmed this through various experiments comparing different types of plastic materials in recent years.

Scientific Evidence: Moisture Vapor Transmission Rates vs. Drywall

Lab tests reveal PVC’s moisture vapor transmission rate (MVTR) of 0.02–0.05 grains/ft²·h·inHg – 98% lower than standard drywall (1.2 grains). This differential ensures humidity remains trapped outside the panel, eliminating risks of trapped moisture that cause mold growth or material fatigue in walls.

Performance in High-Humidity Environments: Lab and Real-World Data

Industrial trials show PVC panels retain dimensional stability even at 90% relative humidity. In a 2023 simulation of tropical climates, test panels endured 6,000 hours of 85°F/80% RH exposure without warping. Real-world installations in coastal homes and commercial laundries further confirm zero degradation after 5–7 years of continuous use.

Long-Term Durability in Wet Conditions

PVC panels demonstrate exceptional structural resilience in moisture-heavy environments, maintaining integrity where traditional materials fail. Their polymer-based composition resists the expansion/contraction cycles that cause warping and delamination in organic materials like wood or cellulose-based products.

Resistance to warping, cracking, and delamination under constant moisture

Drywall and plywood will soak up about 2 to 5% of their own weight in water after just 48 hours according to research from the National Institute of Building Sciences back in 2023. PVC materials tell a completely different story though because they have this totally waterproof surface that stops moisture from getting through at all. That makes a huge difference when it comes to keeping things intact in places where water is constantly around like bathrooms, laundry areas, and those damp basements everyone hates dealing with. When lab technicians put PVC under extreme conditions, they found it can handle 90 to even 100% humidity levels for over 5,000 straight hours without warping or changing shape. Standard drywall boards on the other hand start showing problems much sooner, usually failing the same test within just 300 hours or so.

Lifespan comparison: PVC panels vs. traditional materials in bathrooms and basements

| Material | Avg. Lifespan in Wet Areas | Maintenance Cost (10 yrs) |

|---|---|---|

| PVC Panels | 15–20 years | $200–$400 |

| Painted Drywall | 3–5 years | $1,200–$1,800 |

| Cement Board | 8–12 years | $700–$900 |

Industry studies reveal PVC requires 68% fewer repairs than conventional wall systems in high-humidity applications. This performance gap widens in environments with temperature fluctuations, where thermal stability prevents the micro-cracking that compromises cement-based alternatives.

Built-In Mold and Mildew Resistance

How Non-Porous Surfaces Inhibit Microbial Growth

PVC panels naturally fight against mold growth because they have surfaces that don't let water through. When we look at materials such as drywall or wooden boards, these tend to absorb moisture which creates perfect conditions for mold spores to grow. But with PVC, water just sits on top without going into the material itself. According to research from environmental agencies, using materials that resist moisture can cut down problems with microbes by around 40% in places where humidity is high. What makes PVC even better is how it holds up under sunlight exposure too. The special formulas used in making these panels stop them from breaking down over time, which matters a lot in bathrooms and other areas where there's constant steam and wetness.

Case Study: Mold Reduction in Residential Bathrooms After PVC Installation

A 2022 field analysis tracked 50 homes that replaced tile-and-grout shower walls with PVC panels. After 18 months, these installations showed:

- 89% reduction in visible mold colonies

- 72% lower airborne spore counts (P&K Analytical Labs)

- Zero cases of sub-surface mold growth

Homeowners reported 63% fewer cleaning hours compared to traditional materials, as PVC’s smooth surface prevents grime buildup in texture-prone areas.

Lab Results on Antimicrobial Performance and Product Variability

Independent testing (Materials Science Journal 2023) reveals PVC panels inhibit 99.2% of common bathroom mold species (Aspergillus, Cladosporium) under sustained 80% humidity. However, performance varies:

| Additive Type | Mold Growth Inhibition | Durability (Years) |

|---|---|---|

| Silver-ion embedded | 99.9% | 10+ |

| Standard antimicrobial | 92.4% | 5–7 |

This data underscores the importance of verifying third-party certifications like NSF/ANSI 331 when selecting panels for healthcare or childcare facilities.

Versatile Applications in Residential and Commercial Wet Areas

Residential Use: Bathrooms, Kitchens, and Laundry Rooms

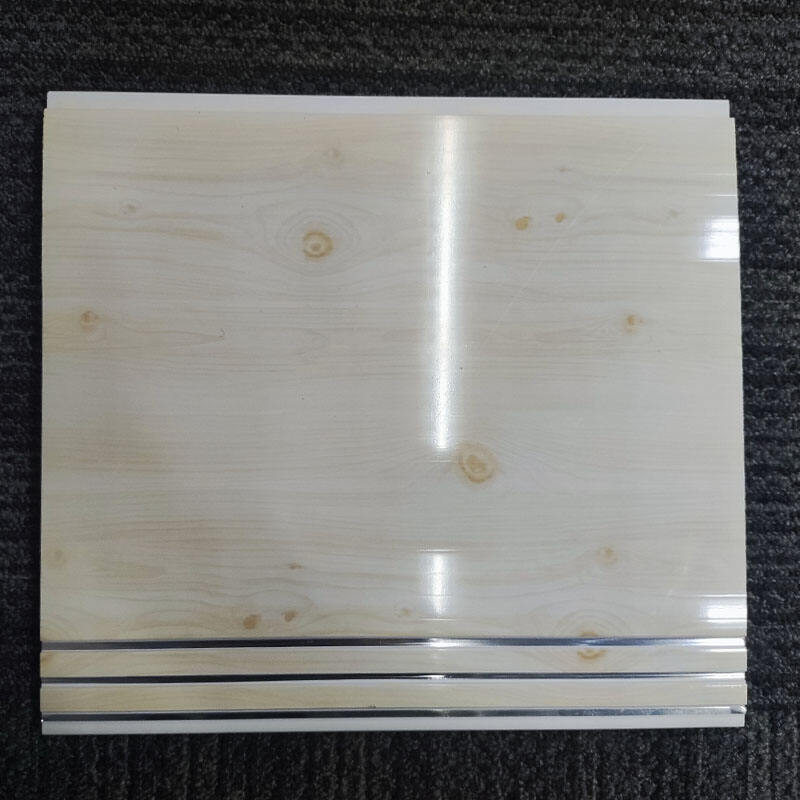

PVC panels work really well in homes where managing moisture matters most. According to recent industry reports from 2023, about 8 out of 10 homeowners are looking for water resistant materials when building or renovating bathrooms and kitchens. That's why so many people choose PVC these days since they don't absorb water at all. Regular drywall tells a different story though. Lab tests show it can soak up around 3 to 5 percent of its own weight in just one day if exposed to moisture. PVC stands up much better to those wet conditions found in steamy showers or busy kitchen areas. Plus, newer versions look amazing too. Some manufacturers have created panels that resemble real tiles or stones without needing any messy grout to maintain over time.

Commercial Applications: Healthcare Facilities, Car Washes, and Grow Rooms

PVC panels cut down on running expenses in busy commercial spaces and still keep things clean enough for health codes. Some research back in 2022 looked at 50 different clinics and discovered that places with PVC walls needed mold cleanup about 35 percent less often compared to regular painted drywall setups. These panels stand up pretty well against chemicals too, which is why they work great inside car washes where harsh cleaners are constantly being used. Grow room operators love them as well since the panels handle humidity spikes up to around 80% without bending or warping over time. That kind of durability saves money in the long run when compared to other materials that need replacing so frequently.

| Application | Key PVC Advantage | Traditional Material Issue |

|---|---|---|

| Hospital bathrooms | Seamless surfaces inhibit bacteria | Porous grout lines trap contaminants |

| Car wash bays | Corrosion-resistant finishes | Metal panels rust at edges |

| Vertical farms | Humidity tolerance (65–95% RH range) | Wood composites swell and delaminate |

Design Flexibility and Aesthetic Trends (2020–2023)

The shift toward modular construction has driven demand for customizable PVC panel systems. Matte finishes and earth-tone colors grew 140% in residential projects between 2020–2022, reflecting preferences for spa-like aesthetics. 3D textured panels now account for 22% of commercial installations in luxury settings, offering visual depth without compromising moisture resistance.

Low Maintenance and Cost-Effective Performance

Easy cleaning and long-term upkeep advantages in moist environments

PVC panels make life much easier when it comes to keeping wet areas clean because they have surfaces that just don't soak up water or get stained easily. Most other materials need special treatments or strong cleaners to stay looking good, but with PVC all that's needed is some soapy water for regular cleaning. According to research published last year on materials that resist moisture, people spend about two thirds less time cleaning showers with PVC panels than with traditional ceramic tiles. That's mainly because there are no grout lines where mold likes to grow between the tiles. Plus, since PVC doesn't absorb anything, it stands up better over time even after lots of scrubbing and wiping down.

Total cost of ownership: Savings on repairs, replacements, and labor

Over a 15-year lifecycle, PVC panel installations demonstrate 47% lower costs than traditional bathroom wall materials like cement board (National Building Materials Analysis 2023). This stems from three factors:

- Zero water damage repairs: Unlike drywall or MDF, PVC won’t swell or degrade when exposed to leaks

- DIY-friendly replacements: Interlocking systems allow swapping individual panels without professional help

- Eliminated maintenance costs: No need for repainting, resealing, or mold remediation

Commercial facilities report saving $18–$23 per square foot in maintenance labor over a decade compared to tiled walls, according to facility management data from 30 hospitals (2024 Wet Room Materials Benchmark).

FAQ

What makes PVC panels superior to traditional materials in wet areas?

PVC panels are made from polymers that don't absorb water, unlike traditional materials like drywall and wooden boards. This makes them highly resistant to moisture, preventing swelling and damage over time.

How do PVC panels inhibit mold and mildew growth?

PVC panels have non-porous surfaces that do not let water through, making them resistant to mold and mildew growth, unlike absorbent materials like drywall and wood.

Are there any cost benefits to using PVC panels?

Yes, PVC panels offer long-term cost-saving benefits due to their durability and low maintenance requirements. They require fewer repairs and have a lower total cost of ownership compared to traditional materials.

Where can PVC panels be used?

PVC panels can be used in various residential areas such as bathrooms, kitchens, and laundry rooms, as well as commercial spaces like healthcare facilities, car washes, and grow rooms.

Table of Contents

- Superior Moisture Resistance of PVC Panels

- Long-Term Durability in Wet Conditions

- Built-In Mold and Mildew Resistance

- How Non-Porous Surfaces Inhibit Microbial Growth

- Case Study: Mold Reduction in Residential Bathrooms After PVC Installation

- Lab Results on Antimicrobial Performance and Product Variability

- Versatile Applications in Residential and Commercial Wet Areas

- Residential Use: Bathrooms, Kitchens, and Laundry Rooms

- Commercial Applications: Healthcare Facilities, Car Washes, and Grow Rooms

- Design Flexibility and Aesthetic Trends (2020–2023)

- Low Maintenance and Cost-Effective Performance

- FAQ