Core Properties and Selection Criteria for 3D Wall Panels

Understanding the Role of Material Choice in 3D Wall Panel Performance

What materials we choose has a big impact on how well 3D wall panels hold up over time, last through different conditions, and work properly in their intended spaces. Take bathroom installations for example moisture resistant PVC stays stable even when exposed to humidity, whereas wooden panels tend to warp unless installed somewhere with controlled temperature and humidity levels. According to a recent industry report from 2023, about 38 out of every 100 early panel failures were traced back to poor material choices. That makes sense when thinking about it because selecting the right stuff upfront saves headaches down the road, especially considering factors like where they'll be placed and what kind of weight or stress they might need to support.

Key Factors Influencing Material Selection: Durability, Moisture Resistance, and Aesthetics

Three primary criteria govern 3D wall panel material choices:

- Durability: High-traffic areas demand impact-resistant options like stone composites or metal

- Moisture Resistance: Waterproof PVC and WPC (Wood Plastic Composite) outperform organic materials in humidity-prone zones

- Aesthetic Flexibility: Engineered wood and MDF (Medium-Density Fiberboard) allow precise carving for intricate designs

Material lifespan varies dramatically—outdoor PVC panels last 10—15 years, while untreated wood may degrade within 5 years in humid climates.

Common Materials Used in 3D Wall Panels

| Material | Key Properties | Ideal Applications |

|---|---|---|

| PVC | Waterproof, UV-resistant, lightweight | Bathrooms, exterior façades |

| WPC | Mold-resistant, wood-like texture | Kitchens, commercial spaces |

| MDF | Smooth paintable surface, budget-friendly | Dry interior feature walls |

| Natural Wood | Biodegradable, premium aesthetics | Climate-controlled lobbies |

| Stone Veneer | Fire-resistant, architectural grandeur | Luxury retail environments |

Hybrid materials like fabric-coated acoustic panels are gaining traction, merging functional performance with avant-garde design possibilities.

Popular 3D Wall Panel Materials: PVC, MDF, and Wood-Based Options

Waterproof and UV-Resistant PVC 3D Wall Panels for Interior and Exterior Use

PVC panels dominate moisture-prone spaces like bathrooms and kitchens, offering 95% humidity resistance (Material Performance Report 2024). Their UV-stabilized formulations enable exterior applications such as patio walls without warping or fading, achieving up to 12 years of service life in temperate climates.

Lightweight Design and Easy Installation of PVC Panels

Weighing 1.8—2.4 kg/m²—65% lighter than ceramic tiles—these panels install using adhesive or interlocking systems. Contractors report 40% faster installations compared to MDF, requiring only basic tools like a utility knife and level.

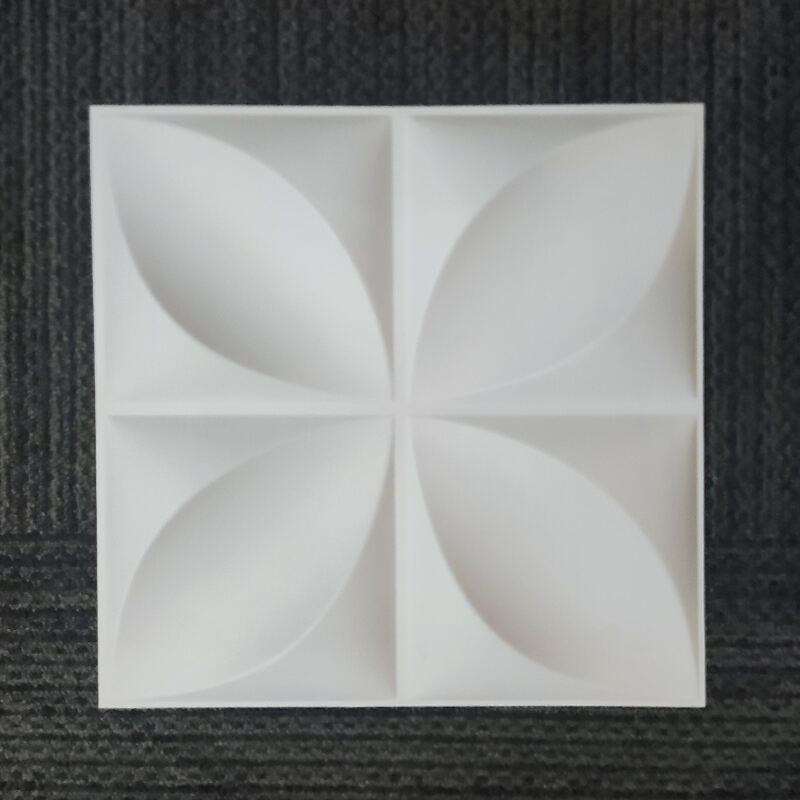

Precision Carving and Smooth Finish Capabilities of MDF Panels

Medium-density fiberboard (MDF) supports intricate designs down to 0.5 mm detail fidelity, making it ideal for ornate geometric patterns. Post-carving surface finishing achieves Ra 0.8—1.6 ¼m smoothness, providing optimal bases for high-gloss paints and wood-effect veneers.

Cost-Effectiveness and Limitations of MDF in Moisture-Prone Areas

While MDF costs $3—$5/sf versus PVC’s $4—$7/sf, its 12% water absorption rate (ASTM D1037) demands protective sealants in humid environments. Untreated panels in bathrooms show deformation within 18—24 months, whereas PVC remains stable for over a decade.

Solid Wood vs. Engineered Wood (WPC): Natural Aesthetics with Structural Integrity

| Characteristic | Solid Wood | WPC |

|---|---|---|

| Moisture Resistance | Moderate | High |

| Expansion Rate | 0.3% RH change | 0.1% RH change |

| Maintenance Frequency | Annual sealing | Biannual cleaning |

Wood-plastic composite (WPC) blends 60% recycled wood fibers with polymer binders, combining natural aesthetics with resistance to mold, insects, and dimensional changes.

Sustainable and Natural Material Options for Eco-Friendly 3D Wall Panels

Rise of Biodegradable Plant Fiber and Natural Material Panels

The market for biodegradable 3D wall panels has grown quite a bit over the past couple years, with demand jumping around 58% since 2022 thanks to new developments in plant based materials. These days, things like bamboo fibers, hemp products, and even leftover bits from farming operations can hold up just as well as conventional building materials but will eventually break down naturally. When it comes to sound absorption, compressed cork panels actually perform pretty close to synthetic options at about 90% effectiveness. That makes these panels especially popular among builders working on green homes or office spaces where both environmental impact and noise control matter.

Performance of Organic Composites in Sound Absorption and Indoor Air Quality

Organic composites enhance indoor environmental quality. Mycelium-based panels reduce airborne VOCs by up to 34% and achieve a noise reduction coefficient (NRC) of 0.75—40% higher than standard drywall. These materials also regulate humidity naturally, maintaining indoor relative humidity within the optimal 45—55% range.

Sustainability and Eco-Friendliness of Responsibly Sourced Wood and Fibers

Third-party certifications like FSC and Cradle to Cradle™ now cover 72% of natural 3D panel production. Closed-loop manufacturing recycles 89% of water used in bamboo processing, while reclaimed wood diverts 11 metric tons per facility monthly from landfills. Hybrid WPC panels extend service life to 25+ years without chemical preservatives.

Durability Challenges and Water Resistance Limitations of Natural-Based Panels

Untreated plant fibers absorb 23% more moisture than PVC in high-humidity settings. Non-toxic silicate coatings improve water resistance by 400%, though they increase costs by 18—22%. For critical zones like bathrooms, hybrid designs with natural veneers over moisture-resistant cores are increasingly preferred.

Luxury and Decorative 3D Wall Panel Materials: Stone, Metal, and Lightweight Composites

Thin Stone Veneer Panels for Premium Architectural Accents

The thin stone veneer 3D panels give that authentic natural stone appearance while weighing about 85% less than real stone thanks to materials like high density polyurethane or fiber cement backing. These panels are pretty slim too, generally less than half a centimeter thick, which makes them perfect for replicating those classic slate and travertine looks on accent walls around fireplaces or anywhere else where the wall doesn't need to support heavy loads. Manufacturers have developed some really convincing techniques these days that produce edges and mineral veins so realistic they almost look like the genuine article. Plus these panels stand up well to sunlight exposure and represent a much more affordable option compared to actual natural stone that typically costs between forty five and a hundred dollars per square foot when installed.

Metal 3D Wall Panels: Corrosion Resistance and Industrial Design Appeal

When it comes to metal 3D panels, powder coated aluminum stands out as a top performer, offering between 500 to 1500 hours of salt spray resistance according to ASTM B117 standards. This makes them ideal choices for areas near coastlines or places with high humidity levels. For those looking to create that modern industrial look in commercial settings, brushed nickel and black oxide finishes are excellent options that still maintain functionality. The modular interlocking system allows for creative geometric arrangements without visible seams. Panels typically range from 0.8 to 1.5 mm in thickness, striking a good balance between being sturdy enough yet light at around 2.7 to 5.1 kilograms per square meter. These characteristics make them particularly well suited for applications in corporate lobbies and various retail environments where both aesthetics and durability matter.

Foam, Styrofoam, and Gypsum-Based Panels for Lightweight Decorative Applications

Expanded polystyrene foam panels are actually the go to option for budget decorating jobs, typically priced between about $2.50 and $4.50 per square foot. These panels can create pretty decent relief depths of around 25mm which works great for things like ceiling medallions or temporary displays. When it comes to gypsum composites mixed with glass fibers, these materials hit Class A fire rating standards, so they're commonly found in places like hotel hallways and apartment buildings where safety regulations matter most. While they won't hold up outside, what makes these composites special is how easily they can be shaped into complex designs such as detailed flowers or elaborate geometric patterns that would be impossible to achieve with standard rigid materials on the market today.

Comparative Analysis of 3D Wall Panel Materials by Performance and Value

Durability, moisture resistance, and suitability across common 3D wall panel materials

When it comes to moisture resistance, PVC stands out as a top choice for bathroom walls and outdoor spaces because it just doesn't care about water damage. On the flip side, MDF absolutely needs some kind of sealant applied if we want it to survive even moderate humidity levels without turning into something unrecognizable. Natural wood still has that classic look nobody can really beat, though homeowners should be prepared for ongoing work like sanding and refinishing every few years to keep mold at bay. For places where people are constantly walking all over things, metal panels make sense since they basically ignore foot traffic and last forever. Stone veneers take a different approach altogether by offering both long life expectancy and that fancy upscale appearance many designers crave for their projects.

Sound absorption, insulation, and environmental impact comparison

Denser materials like MDF and fabric-based panels reduce noise transmission by up to 50% compared to rigid composites. Natural fiber composites offer 72% lower carbon emissions during production (Sustainable Materials Report 2023), outperforming PVC in eco-friendliness. However, synthetic foams like Styrofoam provide better thermal insulation for energy-efficient buildings.

Lifecycle cost, maintenance needs, and aesthetic longevity of 3D panel materials

| Material | Upfront Cost | Annual Maintenance | Aesthetic Lifespan |

|---|---|---|---|

| PVC | $4—$7/sq.ft | $0.30 | 8—12 years |

| Engineered Wood | $9—$15/sq.ft | $1.20 | 15—25 years |

| Bamboo Fiber | $6—$10/sq.ft | $0.50 | 20+ years |

Engineered wood retains its finish three times longer than untreated MDF in homes, though it benefits from seasonal humidity control.

Balancing upfront cost with long-term ROI in commercial and residential spaces

Hotels and offices often select aluminum or stone panels for their 30-year service life, offsetting initial costs through minimal replacement needs. Homeowners typically prefer PVC or bamboo composites, which offer 10—15 years of low-maintenance use at 40% lower lifetime costs than traditional plaster.

FAQ Section

Q: What are the most popular materials for 3D wall panels?

A: The most popular materials are PVC, MDF, and wood-based options, due to their flexibility, durability, and aesthetic appeal.

Q: How does moisture impact 3D wall panels?

A: Moisture can cause some materials to degrade or warp over time. Choosing moisture-resistant options like PVC or WPC for humid areas is crucial.

Q: What factors should be considered when selecting 3D wall panel materials?

A: Considerations should include durability, moisture resistance, aesthetic flexibility, and the specific application environment.

Q: What are hybrid 3D wall panels?

A: Hybrid panels are those made from a combination of materials, such as fabric-coated acoustic panels, which merge function with avant-garde design.

Q: Are there eco-friendly options for 3D wall panels?

A: Yes, biodegradable plant fiber panels such as those made from bamboo and hemp are eco-friendly options that are gaining popularity.

Q: How do MDF panels compare to PVC panels in terms of installation and cost?

A: MDF panels allow for intricate carvings but require protective seals in humid areas. They are generally less expensive than PVC panels per square foot but may require more maintenance in damp conditions.

Table of Contents

- Core Properties and Selection Criteria for 3D Wall Panels

-

Popular 3D Wall Panel Materials: PVC, MDF, and Wood-Based Options

- Waterproof and UV-Resistant PVC 3D Wall Panels for Interior and Exterior Use

- Lightweight Design and Easy Installation of PVC Panels

- Precision Carving and Smooth Finish Capabilities of MDF Panels

- Cost-Effectiveness and Limitations of MDF in Moisture-Prone Areas

- Solid Wood vs. Engineered Wood (WPC): Natural Aesthetics with Structural Integrity

- Sustainable and Natural Material Options for Eco-Friendly 3D Wall Panels

- Luxury and Decorative 3D Wall Panel Materials: Stone, Metal, and Lightweight Composites

-

Comparative Analysis of 3D Wall Panel Materials by Performance and Value

- Durability, moisture resistance, and suitability across common 3D wall panel materials

- Sound absorption, insulation, and environmental impact comparison

- Lifecycle cost, maintenance needs, and aesthetic longevity of 3D panel materials

- Balancing upfront cost with long-term ROI in commercial and residential spaces

- FAQ Section