Understanding Wall Panel Materials and Their Core Properties

Choosing the right wall panel material shapes your project’s aesthetics, functionality, and longevity. Modern options range from classic natural wood to advanced composites, each offering distinct advantages. Below, we break down key materials to help you align choices with your design goals and practical needs.

Solid Wood Panels and Their Natural Appeal

Solid wood panels bring warmth and timeless elegance to interiors. Their organic grain patterns create visual depth, ideal for living rooms or accent walls. While durable, they require sealing in humid environments to prevent warping. Popular species like oak, walnut, and cedar age gracefully with proper care.

MDF (Medium-Density Fiberboard) Paneling for Smooth Finishes

MDF provides a uniform, knot-free surface perfect for painted finishes. Made from compressed wood fibers, it resists splitting and accepts coatings evenly. However, it lacks inherent moisture resistance—edges and surfaces must be sealed in areas like kitchens to prevent swelling.

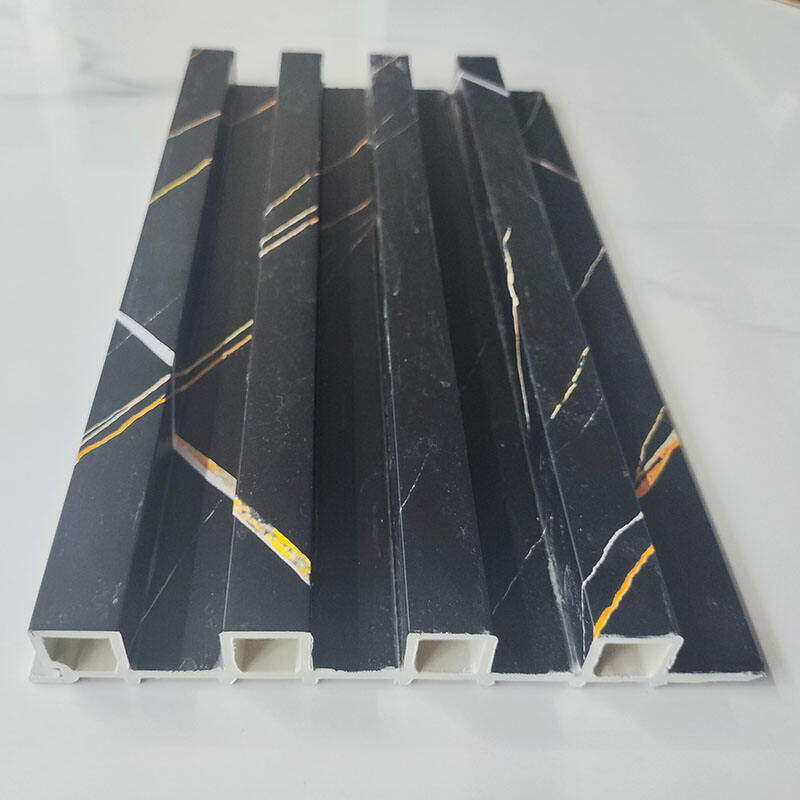

PVC (Polyvinyl Chloride) Paneling for Moisture Resistance

PVC panels are ideal for bathrooms, laundry rooms, and basements due to their waterproof nature. Lightweight and low-maintenance, they resist mold and mildew without sealants. Modern designs convincingly mimic wood or stone textures, combining style with resilience.

Composite Paneling Such as WPC for Hybrid Performance

Wood-plastic composite (WPC) blends recycled wood fibers with polymers, delivering durability in wet or sun-exposed areas. It resists UV fading and thermal expansion, maintaining integrity between -20°F and 140°F. Textured surfaces also minimize the appearance of scratches, making WPC well-suited for high-traffic zones.

Alternative Materials: Metal, Fabric, Stone, and Gypsum Options

Specialized applications benefit from alternatives like metal panels for industrial aesthetics, fabric-wrapped boards for sound absorption, or stone veneers for luxury appeal. Gypsum offers fire resistance and seamless finishes, supporting both safety and modern design in commercial and residential spaces.

Evaluating Durability, Maintenance, and Environmental Resistance

Durability and Longevity of Wood Panels in High-Traffic Areas

Solid wood withstands 8–12 years of use in high-traffic areas when maintained properly. With Janka hardness ratings between 900–1,500 lbf, it resists dents effectively. However, humidity above 55% can cause warping without conditioning. Annual resealing extends lifespan by up to 40% compared to untreated panels (Wood Science Journal 2022).

Moisture Resistance and Lifespan of PVC and Composite Panels

PVC maintains structural integrity in 90–100% humidity for over 15 years thanks to its non-porous surface, which inhibits mold growth. WPC combines moisture resistance with thermal stability, enduring extreme temperatures without cracking. Both materials require only quarterly cleaning, making them ideal for kitchens and bathrooms.

Wear Tolerance of MDF With Proper Sealing and Coating

When coated with polyurethane (2–3 mil thickness), MDF achieves 80% of hardwood’s wear resistance. UV-cured epoxy finishes reduce scratching by 67% in sunlit areas (Materials Performance 2023). Moisture-resistant MDF variants remain stable at up to 70% relative humidity when properly sealed.

Comparative Analysis of Wall Panel Features: Durability Across Materials

| Material | Key Strength | Environmental Resistance | Maintenance Needs | Durability Rating (1–5) |

|---|---|---|---|---|

| Solid Wood | Impact resistance | Moderate humidity | Annual sealing | ★★★★✰ |

| PVC | Waterproof | High humidity | Quarterly cleaning | ★★★★★ |

| WPC Composite | Thermal stability | Extreme temperatures | Biannual inspection | ★★★★✰ |

| Coated MDF | Scratch resistance | Low humidity | Triannual refinishing | ★★★✰✰ |

Assessing Aesthetic Flexibility and Design Customization Options

Wood Grain and Texture Selection for Natural Elegance

Solid wood offers multiple species—including oak, walnut, and teak—each with unique grain characteristics. Premium knot-free grades support minimalist designs, while rustic live-edge styles enhance organic themes. Finishes range from matte oil rubs (35% gloss) to high-gloss lacquers (85% gloss), allowing customization based on lighting and décor.

Popular Wall Panel Patterns and Styles: 3D Slat, Geometric, Organic

- 3D slat systems add depth to compact spaces

- Hexagonal geometric panels suit art deco accent walls

-

Organic wave patterns soften angular architecture

A 2023 interior design survey found 68% of professionals now specify curved profiles over right-angle designs in residential projects.

Finish and Treatment Options to Match Interior Themes

Architects commonly select from four finish categories:

| Finish Type | Best For | Maintenance Cycle |

|---|---|---|

| Pigmented stains | Color-matching décor | 5-year reapplication |

| Clear UV coatings | Sunlit spaces | 7-year durability |

| Textured brush | Tactile feature walls | Low upkeep |

| Metallic leaf | Luxury commercial spaces | Professional refinishing |

Analyzing Functional Performance: Acoustics, Insulation, and Safety

Acoustic Performance of Wood Wall Panels in Living Rooms and Offices

Solid wood reduces reverberation by up to 30% in residential and office settings. Its density absorbs mid-frequency sound waves effectively. An 18mm-thick oak panel achieves a noise reduction coefficient (NRC) of 0.55–0.65, enhancing speech clarity in home theaters and open-plan offices (2024 acoustic materials study).

Sound Absorption Capabilities of Fabric and Composite Panels

Fabric-wrapped and composite panels, including WPC, absorb high-frequency sounds with NRC ratings exceeding 0.75. These are especially effective in recording studios and conference rooms, where they suppress flutter echoes while maintaining moisture resistance.

Using Wall Paneling to Reduce Echo in Gaming Rooms and Media Spaces

Dense composites or perforated MDF with acoustic backing reduce echo times below 0.4 seconds in media rooms. Thickness is critical—25mm panels absorb 40% more low-frequency bass than standard 12mm versions, significantly improving audio quality.

Fire Resistance and Insulation Properties by Material Type

| Material | Fire Resistance | Thermal Insulation (R-value/inch) | Best Use Case |

|---|---|---|---|

| Gypsum | 1-hour rating | 0.45 | Fire-rated partitions |

| Mineral Wool | Non-combustible | 3.0–4.0 | HVAC ducts, exterior walls |

| PVC | Self-extinguishing | 0.25 | Bathrooms, kitchens |

Wood panels need fire-retardant treatments to meet commercial codes, while mineral wool composites offer both sound control and Class A fire resistance. Proper installation prevents insulation gaps that compromise performance.

Selecting the Right Wall Panel by Application and Budget

Suitable applications by room type: living rooms and bedrooms

Solid wood enhances living rooms with its warmth and lasting appeal. In bedrooms, engineered wood or MDF offers a cost-effective alternative with smooth, paintable surfaces. While solid wood supports high-end aesthetics, composites suit modern minimalist interiors seeking low maintenance.

Best panel choices for bathrooms and kitchens using moisture-resistant types

PVC and composite panels perform reliably in humid kitchens and bathrooms, lasting 5–7 years without degradation. Unlike untreated wood—which may deteriorate within 12–18 months—these materials resist warping and mold. Textured PVC adds slip resistance in kitchens, while waterproof composites are optimal for bathroom walls.

Commercial uses in offices and retail: balancing aesthetics and function

Retail environments benefit from metal or high-pressure laminate panels that endure 200+ daily interactions with minimal wear. Offices often use acoustic fabric panels, which reduce ambient noise by 30–40%, improving concentration. Modular systems allow quick reconfiguration during tenant turnovers, adding long-term value.

Cost-benefit analysis: solid wood vs. engineered and synthetic panels

Material costs per square foot vary significantly:

| Material Type | Initial Cost | 10-Year Maintenance Cost | Ideal Climate |

|---|---|---|---|

| Solid Wood | $18–$45 | $8–$12/year | Low-humidity zones |

| Engineered Wood | $9–$25 | $4–$7/year | Temperature-stable |

| PVC | $6–$15 | $1.5–$3/year | High-humidity areas |

Synthetic panels offer 60–70% lifetime savings over wood in damp environments. Though solid wood enhances resale value in luxury homes, engineered options provide wood-like appeal at 40% lower long-term costs, striking a balance between budget and performance.

FAQ

What are the best wall panel materials for high-moisture areas?

PVC and composite panels such as WPC are ideal for high-moisture areas like bathrooms and kitchens due to their moisture resistance and durability.

How do solid wood panels compare to other materials in terms of maintenance?

Solid wood panels require regular sealing, especially in humid areas, whereas PVC and composites need less frequent maintenance, requiring just quarterly cleaning.

What materials offer good acoustic performance?

Solid wood, fabric-wrapped, and composite panels including WPC provide excellent sound absorption capabilities, ideal for living rooms, offices, and media spaces.

How does the cost of synthetic panels compare to solid wood panels?

Synthetic panels are generally more cost-effective over the long term, offering 60-70% savings compared to solid wood in environments with high humidity.

Table of Contents

- Understanding Wall Panel Materials and Their Core Properties

- Evaluating Durability, Maintenance, and Environmental Resistance

- Assessing Aesthetic Flexibility and Design Customization Options

- Analyzing Functional Performance: Acoustics, Insulation, and Safety

- Selecting the Right Wall Panel by Application and Budget

- FAQ