How Soundproof Panels Block Noise Transfer Between Rooms

The Science of Soundproofing: Mass, Density, and Decoupling Explained

There are basically three ways soundproof panels work against unwanted noise: mass, density, and what's called decoupling. When something has mass, it acts as a barrier against sound waves. Think about how thick walls stop sounds from passing through them because they just don't have enough energy to get past that heavy material. Then there's density. Materials that pack a lot into small spaces, like rubber or those mineral wool products, tend to soak up middle and high frequency noises we hear floating around in the air. The third trick is decoupling. This means separating different parts of a structure so vibrations can't travel between them. Builders sometimes install these special channels behind drywall that create gaps between surfaces. These little tricks can cut down on side path noises by maybe half compared to when everything is connected directly together without any space between.

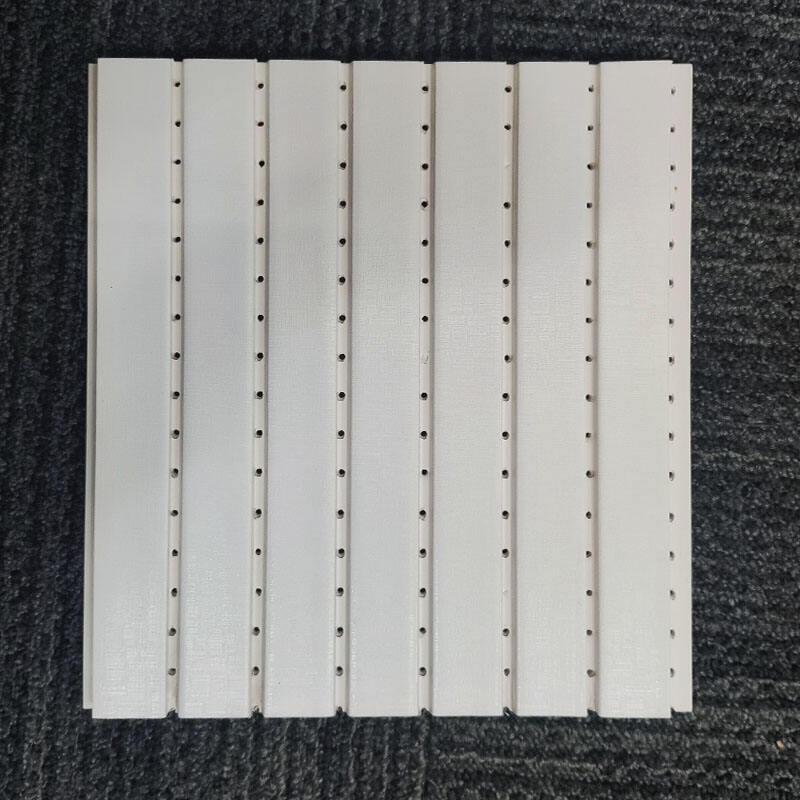

Core Materials in Effective Soundproof Panels: Mass-Loaded Vinyl, Foam Barriers, and Composite Layers

Soundproof panels designed for high performance typically mix mass loaded vinyl, or MLV as it's known in the trade, which weighs around 1 pound per square foot and works really well against those annoying low frequency noises, with closed cell foam that soaks up sounds traveling through air. The composite construction gives these panels extra stiffness while also dampening vibrations across a wide range of frequencies, somewhere between 125 Hz for bass tones all the way up to about 4000 Hz where most speech lives. When used on its own, MLV manages to cut down sound transmission by roughly 12 to 18 decibels. But throw in some mineral wool insulation alongside it and suddenly we're talking about a much bigger difference, somewhere in the neighborhood of 25 to 30 dB reduction, making rooms feel substantially quieter overall.

Real-World Impact: Case Study on Reducing Inter-Room Noise in a Multi-Family Apartment Building

A 2023 study on a 40-unit apartment complex found that installing 2-inch MLV-foam composite panels on shared walls reduced inter-room noise by 70%. Residents reported a 52% drop in complaints about footsteps and voices, and speech privacy scores improved by 43%, meeting ASTM E90 standards for residential sound isolation.

Why Standard Panels Fail and How High-Performance Soundproof Panels Succeed

Basic foam or fiberglass panels absorb only 20–30% of mid-range frequencies and are ineffective against low-frequency noise from appliances or traffic. High-performance panels use multi-layer designs to overcome these limitations:

- Mass: MLV disrupts soundwave energy

- Damping: Viscoelastic adhesives convert vibrations into heat

- Decoupling: Floating mounts prevent structural flanking

This triphasic approach achieves 80–90% noise reduction, outperforming standard panels by 3.5× in controlled tests.

Top Applications of Soundproof Panels in Homes, Offices, and Studios

Improving Focus and Privacy with Soundproof Panels in Open-Plan Offices

Research from Steelcase back in 2022 found that open plan offices actually see around 32% more mistakes caused by distractions from all the background noise. That's where soundproof panels come into play. These panels stop those annoying office sounds right at their source point. The ones made with mass loaded vinyl can cut down on general noise levels somewhere between 8 to 12 decibels. Putting them strategically between different work areas creates pockets of silence where people can concentrate properly or take private calls without being overheard. Some companies tried this out last year and noticed something interesting - their customer service staff completed tasks nearly 19% quicker after installing these acoustic solutions throughout their workspace.

Achieving Professional Recording Quality Through Studio Sound Isolation

Most professional recording studios need to keep outside noise below 45 dB to get decent audio quality. The soundproof panels we typically see are built with multiple layers including gypsum board and special damping materials, which manage to block around 50 to 55 dB of sound transmission. These panels do a pretty good job at keeping out annoying street noises and that constant hum from heating systems. For voiceovers or podcast work specifically, any background noise over 10 dB usually means having to redo takes, which eats into production time and budget. Many professionals also install those peel and stick acoustic seals along the edges of their panels because they really help stop those high frequency sounds that tend to leak through gaps in amateur installations.

Creating Peaceful Residential Environments: Bedrooms, Home Offices, and Shared Walls

Soundproof panels can cut down on airborne noise traveling through shared walls in apartment buildings by around 67%, according to research from the National Research Council back in 2023, especially when they're installed with that staggered stud framing technique. People working from home have noticed something interesting too - those who put up 2 inch thick panels in their office spaces experience about 41% fewer distractions during Zoom calls. And let's not forget about bedrooms where these panels work wonders against outside noises like roaring garbage trucks at midnight or emergency vehicle sirens wailing past windows. Renters aren't left out either since there are freestanding options available now with heavy bases that manage to reduce noise levels between 18 to 22 decibels without needing any drilling or permanent changes to the property. Pretty handy solution if someone wants better acoustics without messing with the building itself.

Soundproof Panels vs. Acoustic Panels: Clarifying the Key Differences

Sound blocking vs. sound absorption: Functional differences that matter

Soundproofing panels and acoustic panels actually do different things altogether. Soundproof panels work by stopping noise from getting through. They use heavy stuff like dense composite materials or mass loaded vinyl, plus some clever decoupling methods. These can cut down on sounds traveling through walls and ceilings by about 90%, which is pretty impressive for most applications. Acoustic panels are quite different though. They're designed to soak up sounds bouncing around inside a space. Made from stuff like foam or fiberglass, they help make rooms sound better but won't stop outside noises much at all. Think of them as fixing echo problems rather than keeping unwanted sounds out completely.

Common misconceptions about acoustic treatment and true soundproofing

A 2023 study revealed that 68% of homeowners mistakenly believe acoustic panels prevent external noise intrusion. Unlike true soundproof panels, acoustic treatments lack the necessary mass to block high-energy sounds like traffic or voices. They help control reverberation within a space but do not stop noise from passing through walls.

When to choose soundproof panels over acoustic panels: A practical decision guide

| Factor | Soundproof Panels | Acoustic Panels |

|---|---|---|

| Primary Purpose | Block noise between rooms/buildings | Reduce echo within a single room |

| Key Materials | Mass-loaded vinyl, damping layers | Porous foam, fiberglass |

| Best Applications | Shared apartment walls, home theaters | Podcast studios, open-plan offices |

Choose soundproof panels when preventing noise transfer is essential. Use acoustic panels to enhance speech clarity or music quality in self-contained spaces.

Installation Best Practices for Maximum Soundproofing Effectiveness

Strategic placement of soundproof panels for optimal noise isolation

The best place to install soundproofing panels is where noise tends to travel most: shared walls account for about 45% of unwanted noise transfer, followed by ceilings at around 30%, and those tricky spots where floors meet ceilings. Don't forget those little details either. Gaps around electrical boxes and places where pipes pass through walls can let in surprising amounts of sound, sometimes responsible for 15 to 20% of all sound leakage according to recent research from Noise Control Journal. When working on walls specifically, combining mass loaded vinyl with properly spaced framing creates much better results, typically reaching STC ratings between 55 and 60. And remember, trying to cover only parts of a wall won't work well at all. Complete coverage matters because studies show that leaving sections uncovered cuts down the whole system's effectiveness by roughly 40%, per findings published by the Acoustical Society last year.

DIY vs. professional installation: Balancing cost, time, and performance

While DIY installations cost 60% less upfront, professional work delivers 25–35% better noise reduction through precise sealing and structural optimization. Key considerations include:

- Project scale (professionals recommended for areas exceeding 300 sq ft)

- Wall construction type (plaster and masonry require specialized mounting)

- Target STC rating (DIY typically maxes out at STC 45, while professional setups exceed STC 60)

Innovative mounting solutions that preserve wall integrity and boost efficiency

Modern soundproof panels utilize three-stage isolation systems:

- Resilient channels (0.8mm steel) that prevent direct wall contact

- Anti-vibration clips reducing structure-borne noise by 18 dB

- Compression-sealed edges maintaining airtight performance

These methods improve noise isolation by 30% compared to direct-mount approaches while causing 80% less wall damage (Building Acoustics Quarterly 2023).

Do peel-and-stick soundproof panels really work? Performance analysis

Peel and stick panels can cut down on airborne noise by around 3 to 5 decibels. That works okay for controlling echoes in small spaces, but they really struggle with impact sounds or those annoying low frequency noises that seem to come through walls. According to tests done by UL certification, panels that are permanently attached using mechanical fasteners actually perform much better than their sticky counterparts. These mechanically fastened solutions beat adhesive options by about 12 to 15 dB across different frequencies. If someone wants better soundproofing without tearing everything apart, mixing peel and stick panels with an MLV underlayer makes a big difference. This combination approach boosts overall performance by roughly 40 percent compared to either method alone.

FAQ

What materials are commonly used in soundproof panels?

Common materials include mass-loaded vinyl, foam barriers, and composite layers which work together to block and dampen sound.

Why might standard foam or fiberglass panels fail to soundproof effectively?

Standard foam or fiberglass panels typically absorb only 20–30% of mid-range frequencies and are not effective against low-frequency noise like traffic or appliances.

How does decoupling in soundproofing panels reduce noise?

Decoupling separates parts of a structure, preventing vibrations from traveling between them and reducing noise transmission.

What is the difference between soundproof and acoustic panels?

Soundproof panels block noise between rooms or through walls, while acoustic panels absorb sounds within a room to reduce echo.

Is professional installation of soundproof panels worth the cost?

Professional installations often provide 25–35% better noise reduction compared to DIY efforts due to expert sealing and setup.

Do peel-and-stick soundproof panels effectively block noise?

Peel-and-stick panels can reduce noise by about 3–5 dB, but are less effective than permanently affixed mechanical fasteners, especially for low-frequency or impact sounds.

Table of Contents

-

How Soundproof Panels Block Noise Transfer Between Rooms

- The Science of Soundproofing: Mass, Density, and Decoupling Explained

- Core Materials in Effective Soundproof Panels: Mass-Loaded Vinyl, Foam Barriers, and Composite Layers

- Real-World Impact: Case Study on Reducing Inter-Room Noise in a Multi-Family Apartment Building

- Why Standard Panels Fail and How High-Performance Soundproof Panels Succeed

- Top Applications of Soundproof Panels in Homes, Offices, and Studios

- Soundproof Panels vs. Acoustic Panels: Clarifying the Key Differences

- Installation Best Practices for Maximum Soundproofing Effectiveness

-

FAQ

- What materials are commonly used in soundproof panels?

- Why might standard foam or fiberglass panels fail to soundproof effectively?

- How does decoupling in soundproofing panels reduce noise?

- What is the difference between soundproof and acoustic panels?

- Is professional installation of soundproof panels worth the cost?

- Do peel-and-stick soundproof panels effectively block noise?